On Substack, John Robson looks at the Canadian federal government’s lofty climate goals and their pathetic strategies to achieve those goals and the vast chasm between the two:

Forgive us for being fixated on Canada’s climate follies just because we live here. But they are revealing, including the U-turn on EVs that we mentioned last week where the government yanked the steering wheel so hard they did a 360 from banning gasoline vehicles by law to banning them by regulation. Raising the question whether they actually know what they’re doing and, if so, whether they regard themselves as commendably devious or just way smarter than everyone else. We hope not the latter because the policy is going to fail big-time. As Randall Denley just warned in the National Post, “To summarize, the Carney plan relies on electric vehicles (EVs) that Ontario plants don’t produce, a sudden and dramatic new appetite for buying EVs and an imagined export market that doesn’t exist. To top it off, the federal government will provide $2.3 billion in EV rebates that will encourage Canadians to buy cars made elsewhere.” Apart from that, a stroke of genius of the sort that, through decades of diligent effort, has made the nation tragically poorer without hitting any of our targets including the one where they get more humble.

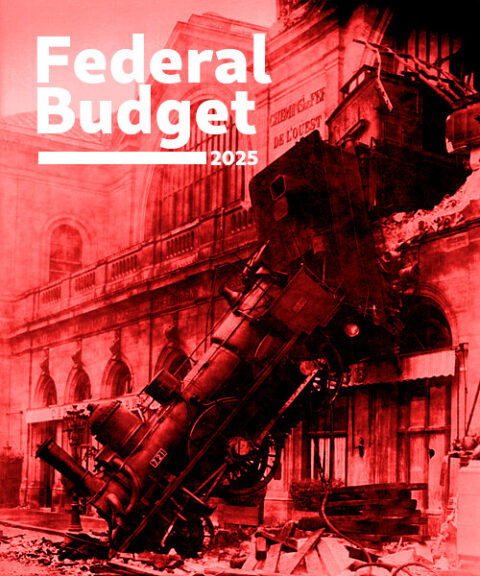

As a Globe & Mail news story blurted out:

A new study published Friday by the Canadian Climate Institute says Canada is not on track to meet any of its climate targets – not the 2026 interim emissions reduction target, the 2030 Paris Agreement commitment, or even the long-term goal of reaching net-zero emissions by 2050.

Oh. Pretty hard to make that one sound like an achievement, isn’t it? Or to sound as if the people who pulled it off should be trusted with the next one.

Now as we’ve complained before, the “Canadian Climate Institute” bills itself as some sort of dispassionate neutral observer when in fact it’s a creature of the state. And, worse, one of those lavishly-funded outfits (we deniers may have all the money, but they got $30 million from the Canadian government and we did not … uh no, that was just one grant, the total’s higher) that exists to push the government to do things it wants to do anyway but needs the appearance of “civil society” support to pull off.

Thus, the Globe sonorously informs us, the problem isn’t that the targets were impractical or the politicians and bureaucrats inept. Heck no. As usual with Thomas Sowell’s “unconstrained vision” of public policy, all you need is love:

The report suggests Canada has moved away from its climate goals thanks to “a slackening of policy effort over the past year, marked by the removal or weakening of climate policies across the country”.

Which gives the impression they had been on track to meet their goals up until some recent backsliding, whereas in reality they have never shown any sign of meeting them. After all, what policies have actually changed since Carney took over as Prime Minister in ways that could possibly affect long-term trends? And how close was Canada to meeting “its climate goals” before this disastrous swerve into the camp of the deniers?

It’s not even true that “Canada” as a collective has collective “climate goals”. The government has climate goals, and they come bundled with a host of other policies at election time, especially since even our “Conservative” party is terrified of challenging climate orthodoxy. Public support for those goals is weak, sporadic and prone to vanish when real costs hove into view. But ignoring that piece of typical collectivist prose, Mark Carney has spent most of his prime ministership flying around virtue-signaling in the presence of others doing the same. (No, really. It’s been less than a year and he’s taken almost three dozen flights.) He hasn’t been in the office shredding this and demolishing that.