Bee Here Now

Published 23 Oct 2023The Stockton-Darlington Railway wasn’t the first time steam locomotives had been used to pull people, but it was the first time they had been used to pull passengers over any distance worth talking about. In 1825 that day came when a line running all the way from the coal pits in the hills around County Durham to the River Tees at Stockton was opened officially. This was an experiment, a practice, a great endeavour by local businessmen and engineers, such as the famous George Stephenson, who astounded crowds of onlookers with the introduction of Locomotion 1 halfway along the line, which began pulling people towards Darlington and then the docks at Stockton.

This was a day that would not only transform human transportation forever, but accelerate the industrial revolution to a blistering pace.

In this video I want to look at what remains of that line — not the bit still in use between the two towns, but the bit out in the coalfields. And I want to see how those early trailblazers tackled the rolling hills, with horses and stationary steam engines to create a true amalgamation of old-world and new-world technologies.

(more…)

February 16, 2024

What remains of the “first” steam powered passenger railway line?

February 7, 2024

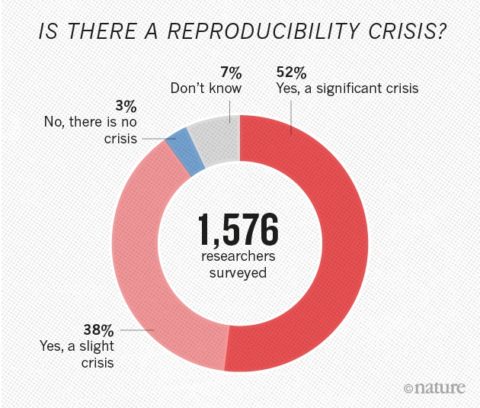

A disturbing proportion of scientific publishing is … bullshit

Tim Worstall on a few of the more upsetting details of how much we’ve been able depend on truth and testability in the scientific community and how badly that’s been undermined in recent years:

The Observer tells us that science itself is becoming polluted by journal mills. Fools — intellectual thieves perhaps — are publishing nonsense in scientific journals, this then pollutes the conclusions reached by people surveying science to see what’s what.

This is true and is a problem. But it’s what people publish as supposedly real science that is the real problem here, not just those obvious cases they’re complaining about:

The startling rise in the publication of sham science papers has its roots in China, where young doctors and scientists seeking promotion were required to have published scientific papers. Shadow organisations – known as “paper mills” – began to supply fabricated work for publication in journals there.

The practice has since spread to India, Iran, Russia, former Soviet Union states and eastern Europe, with paper mills supplying fabricated studies to more and more journals as increasing numbers of young scientists try to boost their careers by claiming false research experience. In some cases, journal editors have been bribed to accept articles, while paper mills have managed to establish their own agents as guest editors who then allow reams of falsified work to be published.

Indeed, an actual and real problem:

The products of paper mills often look like regular articles but are based on templates in which names of genes or diseases are slotted in at random among fictitious tables and figures. Worryingly, these articles can then get incorporated into large databases used by those working on drug discovery.

Others are more bizarre and include research unrelated to a journal’s field, making it clear that no peer review has taken place in relation to that article. An example is a paper on Marxist ideology that appeared in the journal Computational and Mathematical Methods in Medicine. Others are distinctive because of the strange language they use, including references to “bosom peril” rather than breast cancer and “Parkinson’s ailment” rather Parkinson’s disease.

Quite. But the problem is worse, much, much, worse.

Let us turn to something we all can agree is of some importance. Those critical minerals things. We all agree that we’re going to be using more of them in the future. Largely because the whole renewables thing is changing the minerals we use to power the world. We’re — to some extent, perhaps enough, perhaps not enough — moving from using fossil fuels to power the world to using rare earths, silicon, copper and so on to power the world. How much there is, how much useable, of those minerals is important. Because that’s what we’re doing, we’re changing which minerals — from fossil to metallic elements — we use to power the world.

Those estimates of how much there is out there are therefore important. The European Union, for example, has innumerable reports and task forces working on the basis that there’s not that much out there and therefore we’ve got to recycle everything. One of those foundational blocks of the circular economy is that we’ve got to do it anyway. Because there’s simply not enough to be able to power society without the circular economy.

This argument is nads*. The circular economy might be desirable for other reasons. At least in part it’s very sensible too – if it’s cheaper to recycle than to dig up new then of course we should recycle. But that we must recycle, regardless of the cost, because otherwise supply will vanish is that nads*.

But, folk will and do say, if we look at the actual science here we are short of these minerals and metals. Therefore etc. But it’s the science that has become infected. Wrongly infected, infested even.

Here’s the Royal Society of Chemistry and their periodic table. You need to click around a bit to see this but they have hafnium supply risk as “unknown”. That’s at least an advance from their previous insistence that it was at high supply risk. It isn’t, there’s more hafnium out there than we can shake a stick at. At current consumption rates — and assuming no recycling at all which, with hafnium, isn’t all that odd an idea — we’re going to run out sometime around the expected date for the heat death of the universe. No, not run out of the universe’s hafnium, run out of what we’ve got in the lithosphere of our own Earth. To a reasonable and rough measure the entirety of Cornwall is 0.01% hafnium. We happily mine for gold at 0.0001% concentrations and we use less hafnium annually than we do gold.

The RSC also says that gallium and germanium have a high supply risk. Can you guess which bodily part(s) such a claim should be associated with? For gallium we already have a thousand year supply booked to pass through the plants we normally use to extract our gallium for us. For germanium I — although someone competent could be a preference — could build you a plant to supply 2 to 4% of global annual germanium demand/supply. Take about 6 months and cost $10 million even at government contracting rates to do it too. The raw material would be fly ash from coal burning and there’s no shortage of that — hundreds of such plants could be constructed that is.

The idea that humanity is, in anything like the likely timespan of our species, going to run short in absolute terms of Hf, Ga or Ge is just the utmost nads*

But the American Chemistry Society says the same thing:

* As ever, we are polite around here. Therefore we use the English euphemism “nads”, a shortening of “nadgers”, for the real meaning of “bollocks”.

November 22, 2023

Another look at the “Great Divergence”

The latest book review from Mr. and Mrs. Psmith’s Bookshelf features Patrick Wyman’s The Verge: Reformation, Renaissance, and Forty Years that Shook the World:

This is a weird Substack featuring an eclectic selection of books, but one of our recurring interests is the Great Divergence: why and how did the otherwise perfectly normal people living in the northwestern corner of Eurasia managed to become overwhelmingly wealthier and more powerful than any other group in human history? We’ve covered a few theories about what’s behind it — not marrying your cousins, coal, the analytic mindset (twice) — but there are lots of others we’ve never touched, including geographic and thus political fragmentation, proximity to the New World, and even the Black Death. So this is also a book about the Great Divergence, but unlike many of the others it doesn’t offer One Weird Trick to explain things. Instead, Wyman approaches the period between 1490 and 1530 through nine people, each of whom exemplifies one of the many shifts in European society, and so paints a portrait of a changing world.

Of course, he does point to a common thread woven through many of the changes: culture. Or, more specifically, the institutions1 surrounding money and credit that Europeans had spent the last few hundred years developing. But these weren’t themselves dispositive: after all, lots of people in lots of place at lots of times have been able to mobilize capital, and most of them don’t produce graphs that look like this. Really, the secret ingredient was — as Harold Macmillan said of the greatest challenge to his government — “events, dear boy, events”.2 Europe between 1490 to 1530 saw an unusually large number of innovations and opportunities for large-scale, capital-intensive undertakings, and already had the economic institutions in place to take advantage of them. One disruption fed on the next in a mutually-reinforcing process of social, political, religious, economic, and technological change that (Wyman argues) set Europe on the path towards global dominance.

Some of Wyman’s characters — Columbus, Martin Luther, Holy Roman Emperor Charles V — are intensely familiar, but he presents them with verve, as interested in giving you a feel for the individual and their world as in conveying biographical detail. (This is an underrated goal in the writing of history, but really invaluable; the “Cross Section: View from …” chapters were always my favorite part of Jacques Barzun’s idiosyncratic doorstopper From Dawn to Decadence.) This is particularly welcome when it comes to the chapters featuring some lesser-known figures: you may have heard of Jakob Fugger, but unless you’re a Wimsey-level fan of incunabula you’re probably unfamiliar with Aldus Manutius. One-handed man-at-arms Götz von Berlichingen becomes our lens for the chapter about the Military Revolution not because he played a particularly significant role but because he wrote a memoir, and small-time English wool merchant John Heritage is notable pretty much solely because his account book happened to survive into the present. But even with the stories “everyone knows”, Wyman takes several large steps back in order to contextualize that common knowledge: for example, were you aware that while before 1492 Columbus didn’t take any particularly unusual voyages, he did take an unparalleled number and variety of them, making him one of the best-travelled Atlantic sailors of his day? Did you know that Isabella’s inheritance of the Castilian throne was far from certain?3

As the book continues, Wyman can reference the cultural and technological shifts he described in earlier chapters. For instance, much of the Fuggers’ wealth came in the form of silver from deep new mines in the Tyrol. Building the mines required substantial capital — for their new, deeper tunnels and the expensive pumps to drain them, as well as for the furnaces and workshops to separate the copper from the silver via the relatively inefficient liquation process — and while everyone knew all along that the metals were there, it took the combination of a continent-wide bullion shortage and a rising demand for copper to cast bronze cannon (look back to the chapters on state formation and the military!) to make it worth anyone’s while to get them out. But it wasn’t only the Fuggers who made their money in these new mines: the money for Martin Luther’s education came from his father’s small-scale copper mining concern in eastern Germany. Grammar school in his hometown, a parish school nearby, and then four years at university cost Luther pater enough that he couldn’t follow it up for his younger sons (and from his point of view the was probably squandered when Martin became a monk instead of the intended lawyer who would be an asset in the frequent mining disputes), but such an education for even one son would have been out of reach if not for the printed texts on grammar, philosophy and law that made it all far more affordable.

Of course, the relationship between Luther and printing goes both ways. While Luther’s very existence as an educated man was enabled by the printing press, it was the intellectual and religious ferment he would kick off that made printing work.

1. Wyman glosses the term as “a shared understanding of the rules of a particular game … the systems, beliefs, norms and organizations that drive people to behave in particular way”, but it’s more or less what I’ve elsewhere called bundles of social technologies.

2. Apparently he may not have said this, but he should have so print the legend.

3. Isabella’s opponent, her half-niece Joanna, was married to King Afonso V of Portugal, so perhaps some degree of Iberian unification might still have followed. On the other hand, Afonso already had an adult son (King João II, widely admired as “the Perfect Prince” — Isabella always referred to him simply as el Hombre, “the Man”) who would have had no personal claim to Castile. Joanna and Afonso’s marriage was annulled on the perfectly true grounds of consanguinity — he was her uncle — after they lost the war, so they never had children, but if she had won perhaps João (who died without legitimate issue) could have been succeeded by a much younger half-Castilian half-brother. Certainly an Isabella relegated to Queen-Consort of Aragon would still have been a force to be reckoned with, but losing the knock-on effects of her reign (Columbus, Granada, the fate of the Sephardim, not to mention the eventual unification of most of Europe under Ferdinand and Isabella’s Habsburg grandson) makes all this a pretty good setup for an alternate history!

Even more fun: before she married Ferdinand of Aragon, there was discussion of Isabella’s betrothal to Richard, Duke of Gloucester. Yeah, that one.

November 15, 2023

October 28, 2023

The transition from burning wood to burning coal

The latest Age of Invention newsletter touches on some of the details Anton Howes uncovered while researching some work on commission for Britain’s NESTA (formerly the National Endowment for Science, Technology and the Arts):

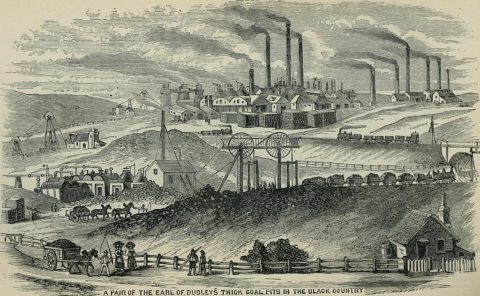

An image of coal pits in the Black Country from Griffiths’ Guide to the iron trade of Great Britain, 1873.

Image digitized by the Robarts Library of the University of Toronto via Wikimedia Commons.

Here are a few key things that I hadn’t really fully appreciated until undertaking this particular commission, though each has provided even more threads I still need to pull on:

ONE. The transition to coal was started by finding ways to exploit the lower-grade, cheaper and more sulphurous coals: initially by finding ways to burn it in people’s homes that would not leave everyone crying and coughing from the stinking fumes; and then with the expanded supply of even the lowest-grade coals making it cost-effective to do things like boil seawater in pans to make salt. The very lowest-grade coal was termed simply “pan coal”. While I’m pretty certain that these innovations were responsible for much of the rise of coal — coal-fuelled salt pans were even the foundation of the Scottish Lowlands economy going into the eighteenth century — the actual inventors involved are still a bit of a mystery. It’s something I need to return to, as “lots of anonymous people just invented through trial and error and adaptation” just doesn’t cut it for me — I’ve never found such stories to be true upon closer investigation.

TWO. Nobody ever talks about lime! Lime was one of the few things burnt with coal since ancient times, but largely to produce mortar for building. The increased availability of cheaper coal in the sixteenth century, however, meant that lime also soon found much wider use as a soil acidity regulator, as well as to control some pests and improve the absorption of fertilisers. It was especially favoured for sandy soils, allowing the conversion of barren heaths to agricultural land by increasing the soil’s water retention.

Yet lime is a huge blind spot for economic historians, despite it increasing the productivity of what was still by far the largest portion of the economy: agriculture. I have a rough and ready test of whether economic historians are paying enough attention to an industry, which is to look up the word in Stephen Broadberry et al.’s British Economic Growth 1270-1870, most scholars’ go-to resource on how historical British output is estimated. Lime is mentioned only once, and only as an input to the construction industry, for mortar. We should know more about lime’s impact.

THREE. Coal, through its various effects on agriculture, also led to an increase in the availability of grain, in turn leading to an abundance of muscle power. Horses were the literal workhorses of industrial cities, grinding the pigments for dyes and paints, tobacco for snuff, charred bones for shoe polish, tannin-rich oak bark for leather, flint for glass and ceramics, and grain for flour, beer, and spirits. Horses fulled cloth, pounded rags into paper, flatted metal into sheets, and bored pipes, guns and even cannon. And of course they powered the transportation infrastructure, hauling the waggons and barges laden with goods.

A theme I keep coming across when I do my research is that there was a lot of effort put into what we might call the “improvement of animals”. I’ve touched on this briefly before, but I get a sense that there’s a whole lot of iceberg lying in wait under the surface for me to uncover. It likely extended to dogs, for example, who like horses were also often used for mechanical tasks. Just yesterday, for example, I read an account by a visitor to 1630s Bristol mentioning how the roasting spits at its inns were driven by dogs in treadwheels. At some point I need to go through all this evidence I’ve inadvertently collected.

FOUR. The Dutch Republic’s Golden Age did not fail because it lacked energy sources. I had already suspected this, as it never rang true, but had not quite appreciated the extent of the evidence: the fairly rapid collapse of so many Dutch industries in the 1650s-80s was, if anything, accompanied by a super-abundance of energy. Both peat and grain were in fact cheaper than ever, largely as a result of plummeting demand. Even the products made using wind —such as the timber sawn for ships along the windy banks of the Zaan river — failed to survive the general collapse in demand.

If energy had been lacking, we would have expected the prices of peat and grain to have been at all-time highs, not in a slump. Indeed, the lack of demand for peat and grain, by sapping demand for infrastructure projects like bog drainage and canal-building, is what led to the re-flooding of much of the Dutch countryside. The causes of the collapse are still something of a mystery to me, but I now feel very confident in ruling the energy theory out.

September 12, 2023

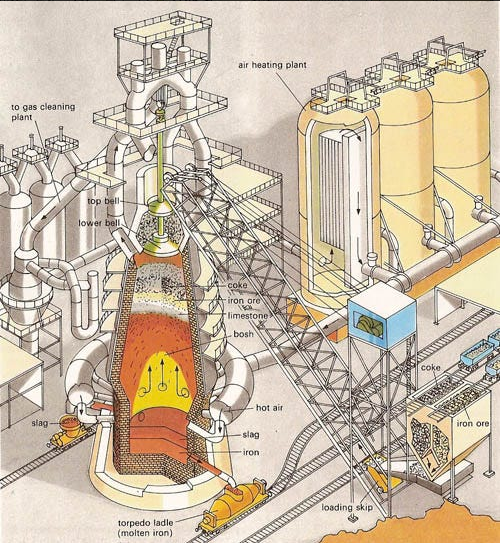

QotD: The largest input for producing iron in pre-industrial societies

… let’s start with the single largest input for our entire process, measured in either mass or volume – quite literally the largest input resource by an order of magnitude. That’s right, it’s … Trees

The reader may be pardoned for having gotten to this point expecting to begin with exciting furnaces, bellowing roaring flames and melting all and sundry. The thing is, all of that energy has to come from somewhere and that somewhere is, by and large, wood. Now it is absolutely true that there are other common fuels which were probably frequently experimented with and sometimes used, but don’t seem to have been used widely. Manure, used as cooking and heating fuel in many areas of the world where trees were scarce, doesn’t – to my understanding – reach sufficient temperatures for use in iron-working. Peat seems to have similar problems, although my understanding is it can be reduced to charcoal like wood; I haven’t seen any clear evidence this was often done, although one assumes it must have been tried.

Instead, the fuel I gather most people assume was used (to the point that it is what many video-game crafting systems set for) was coal. The problem with coal is that it has to go through a process of coking in order to create a pure mass of carbon (called “coke”) which is suitable for use. Without that conversion, the coal itself both does not burn hot enough, but also is apt to contain lots of sulfur, which will ruin the metal being made with it, as the iron will absorb the sulfur and produce an inferior alloy (sulfur makes the metal brittle, causing it to break rather than bend, and makes it harder to weld too). Indeed, the reason we know that the Romans in Britain experimented with using local coal this way is that analysis of iron produced at Wilderspool, Cheshire during the Roman period revealed the presence of sulfur in the metal which was likely from the coal on the site.

We have records of early experiments with methods of coking coal in Europe beginning in the late 1500s, but the first truly successful effort was that of Abraham Darby in 1709. Prior to that, it seems that the use of coal in iron-production in Europe was minimal (though coal might be used as a fuel for other things like cooking and home heating). In China, development was more rapid and there is evidence that iron-working was being done with coke as early as the eleventh century. But apart from that, by and large the fuel to create all of the heat we’re going to need is going to come from trees.

And, as we’ll see, really quite a lot of trees. Indeed, a staggering number of trees, if iron production is to be done on a major scale. The good news is we needn’t be too picky about what trees we use; ancient writers go on at length about the very specific best woods for ships, spears, shields, or pikes (fir, cornel, poplar or willow, and ash respectively, for the curious), but are far less picky about fuel-woods. Pinewood seems to have been a consistent preference, both Pliny (NH 33.30) and Theophrastus (HP 5.9.1-3) note it as the easiest to use and Buckwald (op cit.) notes its use in medieval Scandinavia as well. But we are also told that chestnut and fir also work well, and we see a fair bit of birch in the archaeological record. So we have our trees, more or less.

Bret Devereaux, “Iron, How Did They Make It? Part II, Trees for Blooms”, A Collection of Unmitigated Pedantry, 2020-09-25.

August 28, 2023

Why Britain Advanced Before Other European Nations | Thomas Sowell

Thomas SowellTV

Published 17 Dec 2021

(more…)

August 15, 2023

QotD: Iron ore processing in pre-industrial societies

Once our ore reaches the surface (or is removed from its open pit) it is not immediately ready for smelting, but has to go through a series of preparatory steps collectively referred to as “dressing” to get the ore ready for its date with the smelter […]

Ore removed from the mine would need to be crushed, with the larger stones pulled out of the mines smashed with heavy hammers (against a rock surface) in order to break them down to a manageable size. The exact size of the ore chunks desired varies based on the metal one is seeking and the quality of the local ore. Ores of precious metals, it seems, were often ground down to powder, but for iron ore it seems like somewhat larger chunks were acceptable. I’ve seen modern experiments with bloomeries […] getting pretty good results from ore chunks about half the size of a fist. Interestingly, Craddock notes that ore-crushing activity at mines was sufficiently intense that archaeologists can spot the tell-tale depressions where the rock surface that provided the “floor” against which the ore was crushed have been worn by repeated use.

Ore might also be washed, that is passed through water to liberate and wash away any lighter waste material. Washing is attested in the ancient world for gold and silver ores (and by Georgius Agricola for the medieval period for the same), but might be used for other ores depending on the country rock to wash away impurities. The simple method of this, sometimes called jigging, consisted of putting the ore in a sieve and shaking it while water passed through, although more complex sluicing systems are known, for instance at the Athenian silver mines at Laurium (note esp. Healy, 144-8 for diagrams); the sluices for washing are sometimes called buddles. Throughout these processes, the ore would also probably be hand-sorted in an effort to separate high-grade ore from low-grade ore.

It’s clear that this mechanical ore preparation was much more intensive for higher-value metals where making sure to be as efficient as possible was a significant concern; gold and silver ores might be crushed, sorted, washed and rewashed before being ground into a powder for the final smelting process. Craddock presents a postulated processing set for copper ore for the Bronze Age Timna mines that goes through a primary crushing, hand-sorted division into three grades, secondary crushing, grinding, a winnowing step for the low-grade ore (either air winnowing or washing) before being blended into the final smelter “charge”.

As far as I can tell, such extensive processing for iron was much less common; in many cases it seems it is hard to be certain because the sources remain so focused on precious metal mining and the later stages of iron-working. Diodorus describes the iron ore on Elba as merely being crushed, roasted and then bloomed (5.13.1) but the description is so brief it is possible that he is leaving out steps (but also, Elba’s iron ore was sufficiently rich that further processing may not have been necessary). In many cases, iron was probably just crushed, sorted and then moved straight to roasting […]

Bret Devereaux, “Iron, How Did They Make It? Part I, Mining”, A Collection of Unmitigated Pedantry, 2020-09-18.

July 29, 2023

July 3, 2023

Three Forgotten Roman Megaprojects

toldinstone

Published 31 Mar 2023The longest tunnel in ancient history. A highway suspended over a raging river. A secret harbor for the Roman navy. These are three of the most impressive Roman engineering projects that you’ve probably never heard of.

(more…)

June 24, 2023

QotD: The plight of miners in pre-industrial societies

Essentially the problem that miners faced was that while mining could be a complex and technical job, the vast majority of the labor involved was largely unskilled manual labor in difficult conditions. Since the technical aspects could be handled by overseers, this left the miners in a situation where their working conditions depended very heavily on the degree to which their labor was scarce.

In the ancient Mediterranean, the clear testimony of the sources is that mining was a low-status occupation, one for enslaved people, criminals and the truly desperate. Being “sent to the mines” is presented, alongside being sent to work in the mills, as a standard terrible punishment for enslaved people who didn’t obey their owners and it is fairly clear in many cases that being sent to the mines was effectively a delayed death sentence. Diodorus Siculus describes mining labor in the gold mines of Egypt this way, in a passage that is fairly representative of the ancient sources on mining labor more generally (3.13.3, trans Oldfather (1935)):

For no leniency or respite of any kind is given to any man who is sick, or maimed, or aged, or in the case of a woman for her weakness, but all without exception are compelled by blows to persevere in their labours, until through ill-treatment they die in the midst of their tortures. Consequently the poor unfortunates believe, because their punishment is so excessively severe, that the future will always be more terrible than the present and therefore look forward to death as more to be desired than life.

It is clear that conditions in Greek and Roman mines were not much better. Examples of chains and fetters – and sometimes human remains still so chained – occur in numerous Greek and Roman mines. Unfortunately our sources are mostly concerned with precious metal mines and those mines also seem to have been the worst sorts of mines to work in, since the long underground shafts and galleries exposed the miners to greater dangers from bad air to mine-collapses. That said, it is hard to imagine working an open-pit iron mine by hand, while perhaps somewhat safer, was any less back-breaking, miserable toil, even if it might have been marginally safer.

Conditions were not always so bad though, particularly for free miners (being paid a wage) who tended to be treated better, especially where their labor was sorely needed. For instance, a set of rules for the Roman mines at Vipasca, Spain provided for contractors to supply various amenities, including public baths maintained year-round. The labor force at Vipasca was clearly free and these amenities seem to have been a concession to the need to make the life of the workers livable in order to get a sufficient number of them in a relatively sparsely populated part of Spain.

The conditions for miners in medieval Europe seems to have been somewhat better. We see mining communities often setting up their own institutions and occasionally even having their own guilds (for instance, there was a coal-workers guild in Liege in the 13th century) or internal regulations. These mining communities, which in large mining operations might become small towns in their own right, seem to have often had some degree of legal privileges when compared to the general rural population (though it should be noted that, as the mines were typically owned by the local lord or state, exemption from taxes was essentially illusory as the lord or king’s cut of the mine’s profits was the taxes). It does seem notable that while conditions in medieval mines were never quite so bad as those in the ancient world, the rapid expansion of mining activity beginning in the 15th century seems to have coincided with a loss of the special status and privileges of earlier medieval European miners and the status associated with the labor declined back down to effectively the bottom of the social spectrum.

(That said, it seems necessary to note that precious metal-mining done by non-free Native American laborers at the order of European colonial states appears to have been every bit as cruel and deadly as mining in the ancient world.)

Bret Devereaux, “Iron, How Did They Make It? Part I, Mining”, A Collection of Unmitigated Pedantry, 2020-09-18.

May 26, 2023

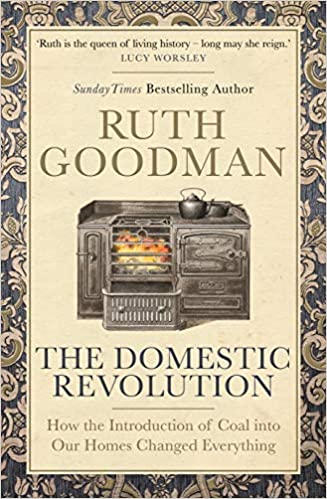

How domestic use of coal transformed Britain

Jane Psmith reviews The Domestic Revolution: How the Introduction of Coal into Victorian Homes Changed Everything by Ruth Goodman:

… Even today, few people record the mundane details of their daily lives; in the days before social media and widespread literacy it was even more dramatic, so anyone who wants to know how our ancestors cleaned, or slept, or ate has to go poking through the interstices of the historical record in search of the answers — which means they need to recognize that there’s a question there in the first place. When they don’t, we end up with whole swathes of the past we can’t really understand because we’re unfamiliar with the way their inhabitants interacted with the physical world.

The Domestic Revolution is about one of these “unknown unknowns”, the early modern English transition from burning wood to coal in the home, and Ruth Goodman may be the only person in four hundred years who could have written it. With exactly the kind of obsessive attention to getting it right that I can really respect, she turned an increasingly intensive Tudor reënactment hobby into a decades-long career as a “freelance historian”, rediscovering as many domestic details of Tudor-era life as possible and consulting for museums and costume dramas. Her work reminds me of the recreations of ancient Polynesian navigational techniques, a combination of research and practical experiments aimed at contextualizing what got remembered or written down, so of course I would love it. (A Psmith review of her How To Be a Tudor is forthcoming.) She’s also starred in a number of TV shows where she and her colleagues live and work for an extended time in period environs, wearing period costume and using period technology1, and because she was so unusually familiar with running a home fired by wood — “I have probably cooked more meals over a wood fire than I have over gas or electric cookers”, she writes — she immediately noticed the differences when she lived with a coal-burning iron range to film Victorian Farm. A coal-fired home required changes to nearly all parts of daily life, changes that people used to central heating would never think to look for. But once Goodman points them out, you can trace the radiating consequences of these changes almost everywhere.

The English switched from burning wood to burning coal earlier and more thoroughly than anywhere else in the world, and it began in London. Fueling the city with wood had become difficult as far back as the late thirteenth century, when firewood prices nearly doubled over the course of a decade or two, and when the population finally recovered from the rolling crises of the fourteenth and fifteenth centuries the situation became dire once again. Wood requires a lot of land to produce, but it’s bulky and difficult to transport by cart: by the 1570s the court of Elizabeth I found it cheapest to buy firewood that had been floated more than a hundred miles down the Thames. Coal, by contrast, could be mined with relative ease from naturally-draining seams near Newcastle-upon-Tyne and sailed right down the eastern coast of the island to a London dock. It already had been at a small scale throughout the Middle Ages, largely to fuel smithies and lime-burners, but in the generation between 1570 and Elizabeth’s death in 1603 the city had almost entirely switched to burning coal. (It had also ballooned from 80,000 to 200,000 inhabitants in the same time, largely enabled by the cheaper fuel.) By 1700, Britain was burning more coal than wood; by 1900, 95% of all households were coal-burning, a figure North America would never match. Of course the coal trade itself had consequences — Goodman suggests that the regular Newcastle run was key in training up sailors who could join the growing Royal Navy or take on trans-Atlantic voyages — and it certainly strengthened trade networks, but most of The Domestic Revolution is driven by the differences in the materials themselves.

The most interesting part of the book to me, a person who is passionately interested in all of human history right up until about 1600, were the details of woodland management under the wood-burning regime. I had, for instance, always assumed that early modern “woodcutters” like Hansel and Gretel’s father were basically lumberjacks chopping down full-grown trees, but actually most trees aren’t killed by removing their trunks. Instead, the stump (or roots, depending on the species) will send up new, branchless shoots, which can be harvested when they reach their desired diameter — anywhere from a year or two for whippy shoots suitable for weaving baskets or fences to seven years for firewood, or even longer if you want thick ash or oak poles for construction. This procedure, called coppicing, also extends the life of the tree indefinitely: an ash tree might live for two hundred years, but there are coppiced ash stools in England that predate the Norman Conquest. (My ignorance here wasn’t entirely chronological provincialism: the pines and other conifers that make up most North American timberland can’t be coppiced.)2 The downside to coppicing is that the new shoots are very attractive to livestock, so trees can also be pollarded — like a coppice, but six or eight feet up the trunk,3 quite a dramatic photo here — which is harder to harvest but means you can combine timber and pasture. This made pollarded “wood pasture” a particularly appealing option for common land, where multiple people had legal rights to its use.4 The woodcutters of the Grimms’ tales probably had a number of fenced coppiced patches they would harvest in rotation, ideally one fell for each year of growth it took to produce wood of the desired size, though a poor man without the upfront capital to support planting the right kind of trees could make do with whatever nature gave him.

There’s plenty more, of course: Goodman goes into great but fascinating detail about the ways different woods behave on the fire (hazel gets going quickly, which is nice for starting a fire or for frying, but oak has staying power; ash is the best of both worlds), the ways you can change the shape and character of your fire depending on what you’re cooking, and the behavior of other regional sorts of fuel like peat (from bogs) and gorse (from heathland). But most of the book is devoted to the differences between burning wood and burning coal, of which there are three big ones: the flame, the heat, and the smoke. Dealing with each one forced people to make obvious practical changes to their daily lives, and in turn each of those changes had second- and third-order consequences that contributed to the profound transformations of the modern period.

The most obvious difference is the fire itself. The flames of wood fires merge together to form a pyramid or spire shape, perfect for setting your pot over: the flames will curl around its nicely rounded bottom to heat it rapidly. Coal, on the other hand, forms “a series of smaller, lower, hotter and bluer flames, spaced across the upper surface of the bed of embers,” suitable for a large flat-bottomed pot. More importantly, though, burning coal requires a great deal more airflow: a coal fire on the ground is rapidly smothered by its own buildup of ash and clinker (and of course it doesn’t come in nice long straight bits for you to build a pyramid out of). The obvious solution is the grate, a metal basket that lifts the coal off the ground, letting the debris fall away rather than clogging the gaps between coals, and drawing cold air into the fire to fuel its combustion. This confines the fire to one spot, which may not seem like a big deal (especially for people who are used to cooking on stoves with burners of fixed sizes) but is actually quite a dramatic change. As Goodman explains, one of the main features of cooking on a wood fire is the ease with which you can change its size and shape:

You can spread them out or concentrate them, funnel them into long thin trenches or rake them into wide circles. You can easily divide a big fire into several small separate fires or combine small fires into one. You can build a big ring of fire around a particularly large pot stood at one end of the hearth while a smaller, slower central fire is burning in the middle and a ring of little pots is simmering away at the far end. You can scrape out a pile of burning embers to pop beneath a gridiron when there is a bit of toasting to do, brushing the embers back into the main fire when the job is done.

In other words, the enormous fireplaces you may have seen in historical kitchens aren’t evidence of equally enormous fires; they were used for lots of different fires of varying sizes, to cook lots of different dishes at the same time. The iron grate for coal, on the other hand, is a fixed size and shape, like a modern burner — though unlike a modern burner the heat is not adjustable. The only thing you can do, really, is put your pot on the grate or take it off.

1. Several of them are streaming on Amazon Prime; I don’t much TV, but I did watch Tudor Monastery Farm with my kids and we all loved it.

2. Some firs can be regrown in a related practice called “stump culture“, which is particularly common on Christmas tree farms, but it’s much more labor-intensive than coppicing.

3. If you live in the southern United States, you’ve probably seen pollarded crape myrtles.

4. Contrary to the impression you may have gotten from the so-called tragedy of the commons, the historical English commons had extremely clearly delineated legal rights. More importantly, these rights all had fabulous names like turbary (the right to cut turves for fuel), piscary (the right to fish), and pannage (the right to let your pigs feed in the woods). I’m also a big fan of the terminology of medieval and early modern tolls, like murage (charged for bringing goods within the walls), pontage (for using a bridge), and pavage (using roads). Since the right to charge these tolls was granted to towns and cities individually, a journey of any length was probably an obnoxious mess of fees (Napoleon had a point with the whole “regulating everything” bit), but you can’t help feeling that “value added tax” is pretty boring by comparison. I suggest “emprowerage”, from the Anglo-Norman emprower (which via Middle English “emprowement” gives us “improvement”) as a much more euphonious name for the VAT. Obviously sales tax should “sellage”. I can do this all day.

April 13, 2023

Old and tired – “Conspiracy Theories”. The new hotness – “Coming Features”

Kim du Toit rounds up some not-at-all random bits of current events:

So Government — our own and furriners’ both — have all sorts of rules they wish to impose on us (and from here on I’m going to use “they” to describe them, just for reasons of brevity and laziness — but we all know who “they” are). Let’s start with one, pretty much picked at random.

They want to end sales of vehicles powered by internal combustion engines, and make us all switch to electric-powered ones. Leaving aside the fact that as far as the trucking industry is concerned, this can never happen no matter how massive the regulation, we all know that this is not going to happen (explanation, as if any were needed, is here). But to add to the idiocy, they have imposed all sorts of unrealistic, nonsensical and impossible deadline to all of this, because:

There isn’t enough electricity — and won’t be enough electricity, ever — to power their future of universal electric car usage. Why is that? Well, for one thing, they hate nuclear power (based on outdated 1970s-era fears), are closing existing ones and will not allow new ones to be built by dint of strangling environmental regulation (passed because of said 1970s-era fears). Then, to add to that, they have forced the existing electricity supply to become unstable by insisting on unreliable and variable generation sources such as solar and wind power. Of course, existing fuel sources such as oil. coal and natural gas are also being phased out because they are “dirty” (they aren’t, in the case of natgas, and as far as oil and coal are concerned, much much less so than in decades past) — but as with nuclear power, the rules are being drawn up as though old technologies are still being used (they aren’t, except in the Third World / China — which is another whole essay in itself). And if people want to generate their own electricity? Silly rabbits: US Agency Advances New Rule Targeting Portable Gas-Powered Generators. (It’s a poxy paywall, but the headline says it all, really.)

So how is this

pixie dust“new” electricity to be stored? Why, in batteries, of course — to be specific, in lithium batteries which are so far the most efficient storage medium. The only problem, of course, is that lithium needs to be mined (a really dirty industry) and even assuming there are vast reserves of lithium, the number of batteries needed to power a universe of cars is exponentially larger than the small number of batteries available — but that means MOAR MINING which means MOAR DIRTY. And given how dirty mining is, that would be a problem, yes?No. Because — wait for it — they will limit lithium mining, also by regulation, by enforcing recycling (where have we heard this before?) and by reducing battery size.

Now take all the above into consideration, and see where this is going. Reduced power supply, reduced power consumption, reduced fuel supply: a tightening spiral, which leads to my final question:

JUST HOW DO THEY THINK THIS IS ALL GOING TO END?

If there’s one thing we know, it’s that increased pressure without escape mechanisms will eventually cause explosion. It’s true in physics, it’s true in nature and it’s true, lest we forget, in humanity.

Of course, as friend-of-the-blog Severian often points out, these people think Twitter is real life. Of course there’ll be enough pixie dust to sprinkle over all their preferred solutions to make them come true. Reality is just a social construct — they learned that in college, and believe it wholeheartedly.

April 4, 2023

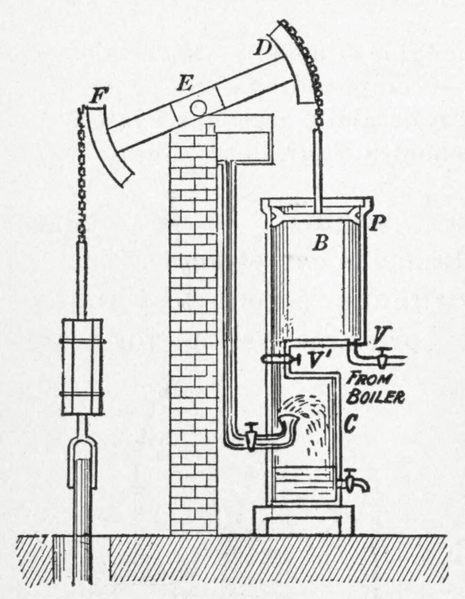

When the steam engine itself was an “intangible”

In the latest Age of Invention newsletter, Anton Howes explains why the steam engine patent of James Watt didn’t immediately lead to Watt and his partner Matthew Boulton building a factory to create physical engines:

Diagram of a Watt steam engine from Practical physics for secondary schools (1913).

Wikimedia Commons.

… one of the most famous business partnerships of the British Industrial Revolution — that between Matthew Boulton and James Watt from 1775 — was originally almost entirely based on intangibles.

That probably sounds surprising. James Watt — a Scottish scientific instrument-maker, chemist and civil engineer — became most famous for his improvements to the steam engine, an almost archetypal example of physical capital. In the late 1760s he radically improved the fuel efficiency of the older Newcomen engine, and then developed ways to regulate the motions of its piston — traditionally applied only to pumping water — so that it could be suitable for directly driving machinery (I’ll write more on the invention itself soon). His partnership with Matthew Boulton, a Birmingham manufacturer of buttons, candlesticks, metal buckles and the like — then called “toys” — was also based from a large, physical site full of specialised machinery: the Soho Manufactory. On the face of it, these machines and factories all sound very traditionally tangible.

But the Soho Manufactory was largely devoted to Boulton’s other, older, and ongoing businesses, and it was only much later — over twenty years after Boulton and Watt formally became partners — that they established the Soho Foundry to manufacture the improved engines themselves. The establishment of the Soho Foundry heralded James Watt’s effective retirement, with the management of this more tangible concern largely passing to his and Boulton’s sons. And when Watt retired formally, in 1800, this coincided with the full depreciation of the intangible asset upon which he and Boulton had built their business: his patent.

Watt had first patented his improvements to the steam engine in 1769, giving him a 14-year window in which to exploit them without any legal competition. But his financial backer, John Roebuck, who had a two-thirds share in the patent, was bankrupted by his other business interests and struggled to support the engine’s development. Watt thus spent the first few years of his patent monopoly as a consultant on various civil engineering projects — canals, docks, harbours, and town water supplies — in order to make ends meet. The situation gave him little time, capital, or opportunity to exploit his steam engine patent until Roebuck was eventually persuaded to sell his two-thirds share to Matthew Boulton. With just eight years left on the patent, and having already wasted six, Boulton and Watt lobbied Parliament to grant them an extension that would allow them to bring their improvements into full use. In 1775 Watt’s patent was extended by Parliament for a further twenty-five years, to last until 1800. It was upon this unusually extended patent that they then built their unusually and explicitly intangible business.

How was it intangible? As Boulton and Watt put it themselves, “we only sell the licence for erecting our engines, and the purchaser of such licence erects his engine at his own expence”. This was their standard response to potential customers asking how much they would charge for an engine with a piston cylinder of particular dimensions. The answer was, essentially, that they didn’t actually sell physical steam engines at all, so there was no way of estimating a comparable figure. Instead, they sold licences to the improvements on a case-by-case basis — “we make an agreement for each engine distinctly” — by first working out how much fuel a standard, old-style Newcomen engine would require when put to use in that place and context, and then charging only a third of the saving in fuel that Watt’s improvements would provide. “The sum therefore to be paid during the working of any engine is not to be determined by the diameter of the cylinder, but by the quantity of coals saved and by the price of coals at the place where the engine is erected.” They fitted the licensed engines with meters to see how many times they had been used, sending agents to read the meters and collect their royalties every month or year, depending on the location.

This method of charging worked well for refitting existing Newcomen engines with Watt’s improvements — in those cases the savings would be obvious. It also meant that Boulton and Watt incentivised themselves to expand the total market for steam engines. The older Newcomen engines were mainly used for pumping water out of coal mines, where the coal to run them was at its cheapest. It was one of the few places where Newcomen engines were cost-effective. But for Watt and Boulton it was at the places where coals were most expensive, and where their improvements could thus make the largest fuel savings, that they could charge the highest royalties. As Boulton wrote to Watt in 1776, the licensing of an engine for the coal mine of one Sir Archibald Hope “will not be worth your attention as his coals are so very cheap”. It was instead at the copper and tin mines of Cornwall, where coal was often expensive, having to be transported from Wales, that the royalties would be the most profitable. As Watt put it to an old mentor of his in 1778, “our affairs in other parts of England go on very well but no part can or will pay us so well as Cornwall”.

March 15, 2023

Mining the moon would be “harmful” to indigenous people, say activists

Among the many, many things that are said to be harmful to indigenous culture we’re now told to include any kind of Lunar exploitation as modern colonialism:

Humans have boldly ventured beyond the Earth into space for more than half a century now. It’s a testament to the ambition of the modern world.

And today, humanity is still more ambitious. A new space race is underway between the US and China to mine the Moon for rare metals. NASA is even hoping to establish a long-term presence on the Moon and eventually send humans to Mars.

But it seems that some scientists-cum-activists, in hock to identity politics, want to rein in that ambition. Speaking ahead of a US conference on the ethics of space exploration, held by the American Association for the Advancement of Science (AAAS) last week, astrobiologist Dr Pamela Conrad told the Guardian that space exploration, particularly efforts to mine the Moon, is in danger of becoming an exercise in “colonialism” and “exploitation”. Conrad warned that “if something that’s not here [on Earth] is seen as a resource, just ripe to be exploited, then that [perpetuates] colonialism”.

Conrad’s fellow panellist at the conference, Dr Hilding Neilson, went even further. According to Neilson, a member of the Native American Mi’kmaq people, indigenous people have a deep connection with celestial bodies like the Moon. They therefore have a more profound and, by implication, superior “way of knowing” the Moon compared with those advocating space exploration. The latter merely see the Moon “as a dead object to be conquered”, Neilson says – meaning that those advocating space exploration are “essentially cheering on the history of colonialism”.

There are so many problems with this argument it’s difficult to know where to start. Both Conrad and Neilson appear to be using the specific and brutal practice of “colonialism” to describe – and demonise – humanity’s attempt to master nature in general. That’s a flawed enough approach to take to the history of our growing mastery of nature on Earth. But it’s even more flawed in the context of space.

After all, there’s one big difference between laying claim to the resources of other countries under colonialism and attempting to mine the Moon – nobody lives on the Moon! So no one would be “exploited” or “colonised” if humans were to mine it. Space exploration is therefore not the same as colonialism.