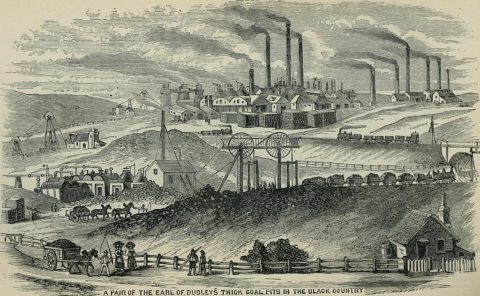

Hoover graduates Stanford in 1895 with a Geology degree. He plans to work for the US Geological Survey, but the Panic of 1895 devastates government finances and his job is cancelled. Hoover hikes up and down the Sierra Nevadas looking for work as a mining engineer. When none materializes, he takes a job an ordinary miner, hoping to work his way up from the bottom […]

Hoover graduates Stanford in 1895 with a Geology degree. He plans to work for the US Geological Survey, but the Panic of 1895 devastates government finances and his job is cancelled. Hoover hikes up and down the Sierra Nevadas looking for work as a mining engineer. When none materializes, he takes a job an ordinary miner, hoping to work his way up from the bottom […]

After a few months, he finds a position as a clerk at a top Bay Area mining firm. One year later, he is a senior mining engineer. He is moving up rapidly – but not rapidly enough for his purposes. An opportunity arises: London company Berwick Moreing is looking for someone to supervise their mines in the Australian Outback. Their only requirement is that he be at least 35 years old, experienced, and an engineer. Hoover (22 years old, <1 year experience, geology degree only) travels to Britain, strides into their office, and declares himself their man. The executives “professed astonishment at Americans’ ability to maintain their youthful appearance” (Hoover had told them he was 36), but hire him and send him on an ocean liner to Australia.

[…]

After a year, Hoover is the most hated person in Australia, and also doing amazing. His mines are producing more ore than ever before, at phenomenally low prices. He scouts out a run-down out-of-the-way gold mine, realized its potential before anyone else, bought it for a song, and raked in cash when it ended up the richest mine in Australia. He received promotion after promotion.

Success goes to his head and makes him paranoid. He starts plotting against his immediate boss, Berwick Moreing’s Australia chief Ernest Williams. Though Williams didn’t originally bear him any ill will, all the plotting eventually gets to him, and he arranges for Hoover to be transferred to China. Hoover is on board with this, since China is a lucrative market and the transfer feels like a promotion. He travels first back to Stanford – where he marries his college sweetheart Lou Henry – and then the two of them head to China.

China is Australia 2.0. Hoover hates everyone in the country and they hate him back […] The same conflicts are playing itself out on the world stage, as Chinese resentment at their would-be-colonizers boils over into the Boxer Rebellion. A cult with a great name – “Society Of Righteous And Harmonious Fists” – takes over the government and encourages angry mobs to go around killing Westerners. Thousands of Europeans, including Herbert and Lou, barricade themselves in the partly-Europeanized city of Tientsin to make a final last stand.

In between dodging artillery shells, Hoover furiously negotiates property deals with his fellow besiegees. He argues that if any of them survive, it will probably because Western powers invade China to save them. That means they will soon be operating under Western law, and people who had already sold their mines to Western companies would be ahead of the game and avoid involuntary confiscation. Somehow, everything comes up exactly how Hoover predicts. US Marines arrived in Tientsin to liberate the city (Hoover marches with them as their local guide) and he is ready to collect his winnings.

Problem: it turns out that “Whatever, sure, you can have my gold mine, we’re all going to die anyway” is not legally ironclad. Hoover, enraged as he watches apparently done deals slip through his fingers, reaches new levels of moral turpitude. He offers the Chinese great verbal deals, then gives them contracts with terrible deals, saying that this is some kind of quaint foreign custom and if they just sign the contract then the verbal deal will be the legally binding one (this is totally false). At one point, he literally holds up a property office with a gun to get the deed to a mine he wants. Somehow, after consecutively scamming half the population of China, he ends up with the rights to millions of dollars worth of mines. Berwick Moreing congratulates him and promotes him to managing director. He and Lou sail for London to live the lives of British corporate bigshots.

As you might also predict, Hoover manages to offend everyone in Britain. Soon he is signing off on a “mutually agreeable”, “amicable” dismissal from Berwick Moreing. They agree to let him go on the condition that he does not compete with them – a promise he breaks basically instantly. He goes into banking, and his “bank” funds mining operations in a way indistinguishable from being a mining conglomerate. Eventually he abandons even this fig leaf, and just does the mining directly.

In other ways, his tens of millions of dollars are mellowing him out. Over his years in London, he develops hobbies besides making money and crushing people. He starts a family; he and Lou have two sons, Herbert Jr and Allen. He even hosts dinner parties, very gradually working on the skill of getting through an entire meal without mortally offending any guest…

Scott Alexander, “Book Review: Hoover”, Slate Star Codex, 2020-03-17.