… Even today, few people record the mundane details of their daily lives; in the days before social media and widespread literacy it was even more dramatic, so anyone who wants to know how our ancestors cleaned, or slept, or ate has to go poking through the interstices of the historical record in search of the answers — which means they need to recognize that there’s a question there in the first place. When they don’t, we end up with whole swathes of the past we can’t really understand because we’re unfamiliar with the way their inhabitants interacted with the physical world.

The Domestic Revolution is about one of these “unknown unknowns”, the early modern English transition from burning wood to coal in the home, and Ruth Goodman may be the only person in four hundred years who could have written it. With exactly the kind of obsessive attention to getting it right that I can really respect, she turned an increasingly intensive Tudor reënactment hobby into a decades-long career as a “freelance historian”, rediscovering as many domestic details of Tudor-era life as possible and consulting for museums and costume dramas. Her work reminds me of the recreations of ancient Polynesian navigational techniques, a combination of research and practical experiments aimed at contextualizing what got remembered or written down, so of course I would love it. (A Psmith review of her How To Be a Tudor is forthcoming.) She’s also starred in a number of TV shows where she and her colleagues live and work for an extended time in period environs, wearing period costume and using period technology1, and because she was so unusually familiar with running a home fired by wood — “I have probably cooked more meals over a wood fire than I have over gas or electric cookers”, she writes — she immediately noticed the differences when she lived with a coal-burning iron range to film Victorian Farm. A coal-fired home required changes to nearly all parts of daily life, changes that people used to central heating would never think to look for. But once Goodman points them out, you can trace the radiating consequences of these changes almost everywhere.

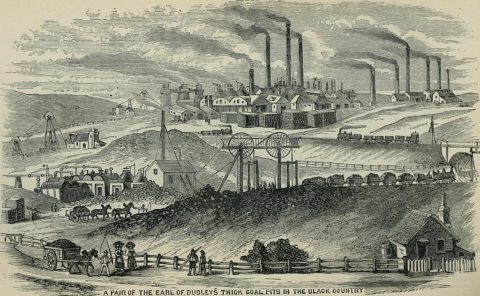

The English switched from burning wood to burning coal earlier and more thoroughly than anywhere else in the world, and it began in London. Fueling the city with wood had become difficult as far back as the late thirteenth century, when firewood prices nearly doubled over the course of a decade or two, and when the population finally recovered from the rolling crises of the fourteenth and fifteenth centuries the situation became dire once again. Wood requires a lot of land to produce, but it’s bulky and difficult to transport by cart: by the 1570s the court of Elizabeth I found it cheapest to buy firewood that had been floated more than a hundred miles down the Thames. Coal, by contrast, could be mined with relative ease from naturally-draining seams near Newcastle-upon-Tyne and sailed right down the eastern coast of the island to a London dock. It already had been at a small scale throughout the Middle Ages, largely to fuel smithies and lime-burners, but in the generation between 1570 and Elizabeth’s death in 1603 the city had almost entirely switched to burning coal. (It had also ballooned from 80,000 to 200,000 inhabitants in the same time, largely enabled by the cheaper fuel.) By 1700, Britain was burning more coal than wood; by 1900, 95% of all households were coal-burning, a figure North America would never match. Of course the coal trade itself had consequences — Goodman suggests that the regular Newcastle run was key in training up sailors who could join the growing Royal Navy or take on trans-Atlantic voyages — and it certainly strengthened trade networks, but most of The Domestic Revolution is driven by the differences in the materials themselves.

The most interesting part of the book to me, a person who is passionately interested in all of human history right up until about 1600, were the details of woodland management under the wood-burning regime. I had, for instance, always assumed that early modern “woodcutters” like Hansel and Gretel’s father were basically lumberjacks chopping down full-grown trees, but actually most trees aren’t killed by removing their trunks. Instead, the stump (or roots, depending on the species) will send up new, branchless shoots, which can be harvested when they reach their desired diameter — anywhere from a year or two for whippy shoots suitable for weaving baskets or fences to seven years for firewood, or even longer if you want thick ash or oak poles for construction. This procedure, called coppicing, also extends the life of the tree indefinitely: an ash tree might live for two hundred years, but there are coppiced ash stools in England that predate the Norman Conquest. (My ignorance here wasn’t entirely chronological provincialism: the pines and other conifers that make up most North American timberland can’t be coppiced.)2 The downside to coppicing is that the new shoots are very attractive to livestock, so trees can also be pollarded — like a coppice, but six or eight feet up the trunk,3 quite a dramatic photo here — which is harder to harvest but means you can combine timber and pasture. This made pollarded “wood pasture” a particularly appealing option for common land, where multiple people had legal rights to its use.4 The woodcutters of the Grimms’ tales probably had a number of fenced coppiced patches they would harvest in rotation, ideally one fell for each year of growth it took to produce wood of the desired size, though a poor man without the upfront capital to support planting the right kind of trees could make do with whatever nature gave him.

There’s plenty more, of course: Goodman goes into great but fascinating detail about the ways different woods behave on the fire (hazel gets going quickly, which is nice for starting a fire or for frying, but oak has staying power; ash is the best of both worlds), the ways you can change the shape and character of your fire depending on what you’re cooking, and the behavior of other regional sorts of fuel like peat (from bogs) and gorse (from heathland). But most of the book is devoted to the differences between burning wood and burning coal, of which there are three big ones: the flame, the heat, and the smoke. Dealing with each one forced people to make obvious practical changes to their daily lives, and in turn each of those changes had second- and third-order consequences that contributed to the profound transformations of the modern period.

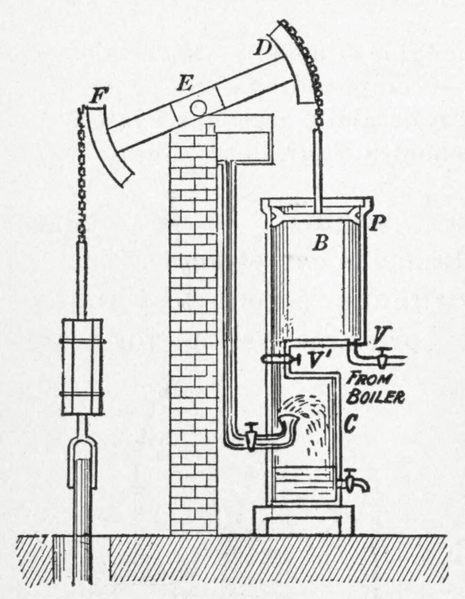

The most obvious difference is the fire itself. The flames of wood fires merge together to form a pyramid or spire shape, perfect for setting your pot over: the flames will curl around its nicely rounded bottom to heat it rapidly. Coal, on the other hand, forms “a series of smaller, lower, hotter and bluer flames, spaced across the upper surface of the bed of embers,” suitable for a large flat-bottomed pot. More importantly, though, burning coal requires a great deal more airflow: a coal fire on the ground is rapidly smothered by its own buildup of ash and clinker (and of course it doesn’t come in nice long straight bits for you to build a pyramid out of). The obvious solution is the grate, a metal basket that lifts the coal off the ground, letting the debris fall away rather than clogging the gaps between coals, and drawing cold air into the fire to fuel its combustion. This confines the fire to one spot, which may not seem like a big deal (especially for people who are used to cooking on stoves with burners of fixed sizes) but is actually quite a dramatic change. As Goodman explains, one of the main features of cooking on a wood fire is the ease with which you can change its size and shape:

You can spread them out or concentrate them, funnel them into long thin trenches or rake them into wide circles. You can easily divide a big fire into several small separate fires or combine small fires into one. You can build a big ring of fire around a particularly large pot stood at one end of the hearth while a smaller, slower central fire is burning in the middle and a ring of little pots is simmering away at the far end. You can scrape out a pile of burning embers to pop beneath a gridiron when there is a bit of toasting to do, brushing the embers back into the main fire when the job is done.

In other words, the enormous fireplaces you may have seen in historical kitchens aren’t evidence of equally enormous fires; they were used for lots of different fires of varying sizes, to cook lots of different dishes at the same time. The iron grate for coal, on the other hand, is a fixed size and shape, like a modern burner — though unlike a modern burner the heat is not adjustable. The only thing you can do, really, is put your pot on the grate or take it off.

1. Several of them are streaming on Amazon Prime; I don’t much TV, but I did watch Tudor Monastery Farm with my kids and we all loved it.

2. Some firs can be regrown in a related practice called “stump culture“, which is particularly common on Christmas tree farms, but it’s much more labor-intensive than coppicing.

3. If you live in the southern United States, you’ve probably seen pollarded crape myrtles.

4. Contrary to the impression you may have gotten from the so-called tragedy of the commons, the historical English commons had extremely clearly delineated legal rights. More importantly, these rights all had fabulous names like turbary (the right to cut turves for fuel), piscary (the right to fish), and pannage (the right to let your pigs feed in the woods). I’m also a big fan of the terminology of medieval and early modern tolls, like murage (charged for bringing goods within the walls), pontage (for using a bridge), and pavage (using roads). Since the right to charge these tolls was granted to towns and cities individually, a journey of any length was probably an obnoxious mess of fees (Napoleon had a point with the whole “regulating everything” bit), but you can’t help feeling that “value added tax” is pretty boring by comparison. I suggest “emprowerage”, from the Anglo-Norman emprower (which via Middle English “emprowement” gives us “improvement”) as a much more euphonious name for the VAT. Obviously sales tax should “sellage”. I can do this all day.