Paul Sellers

Published 25 Jul 2025I have been asked to create this video for some time but couldn’t get to it. Here it is.

All you need is a good sharp chisel. This chisel is an Aldi, £2.50 version, so nothing special. The steps I show guarantee a positive outcome, but please be prepared to put in some practice on a scrap of wood. Avoid softwoods because they have hard and soft aspects surrounding the growth rings which are sometimes difficult to work with. I’m using cherry, but there are many choices that have consistent grain, such as poplar, oak, and walnut.

Carving this star took me a little over half an hour to do. With practice, you will get to understand the grain of the wood, direction and the chiselling techniques I used. I hope you enjoy creating your star!

(more…)

December 18, 2025

How to Carve a Star | Paul Sellers

November 14, 2025

This is in your house … and you’ve never noticed

Rex Krueger

Published 12 Nov 2025The Secret History of Wood – Rubber wood

(more…)

November 4, 2025

Making history the simple way

Rex Krueger

3 Nov 2025yLinks from this video:

History of Raised Panels: https://www.youtube.com/watch?v=M6iIqZY4gvc

Learn About Hardwoods: https://www.youtube.com/watch?v=_NmKfzc3g-I&t=229s

Find and fix up a Rabbet Plane: https://www.youtube.com/watch?v=NcJeu0qMvwc&t=184sGet behind the scenes and FREE plans: https://www.patreon.com/rexkrueger

November 3, 2025

Plastic Fantastic: How the Modern World Became Synthetic – W2W 051

TimeGhost History

Published 2 Nov 2025From the miracle material of the 1950s to the global crisis of the 21st century — this is the story of how plastic reshaped our lives, our economies, and our planet.

Born from wartime innovation, plastic promised a future of convenience, color, and endless possibility. From nylon stockings to Tupperware parties, it defined modern life — light, bright, and disposable. But the same durability that made it revolutionary also made it permanent.

In this episode of War 2 War, we trace how postwar optimism turned into an age of overproduction and pollution — how a chemical miracle became the material legacy of the modern world. Join us as we uncover how the postwar dream of “Better Living Through Chemistry” changed everything — forever.

(more…)

October 28, 2025

AR-1 “Parasniper” – The First Armalite

Forgotten Weapons

Published 11 Jun 2025The first rifle produced by Armalite began in 1952 as a project between the brothers-in-law, Charles Dorchester and George Sullivan (no relation to later Armalite engineer L. James Sullivan). Sullivan is the chief patent attorney for the Lockheed Aircraft Company, and the two have the idea to produce an ultra-light rifle using aircraft industry materials like fiberglass and aluminum. They create a company called SF Projects and get to work using Remington actions. They fit aluminum (and then later aluminum/steel composite) barrels and foam-filled stocks and the result is a rifle that weighs less than 6 pounds with a 4x scope fitted. The first ones are chambered in .257 Roberts, but this shortly gives way to the new .308 Winchester cartridge.

Sullivan and Dorchester make a connection with Richard Boutelle, who is very much a “gun guy” himself and also head of the Fairchild aircraft company. The idea of the rifle appeals to Boutelle, and Fairchild was looking to diversify its operations – and so Fairchild agrees to buy SF Projects, renaming it the Armalite Division of Fairchild.

The idea of the rifle was for civilian hunters who want a gun that is light to carry for long distances and also military specialists like airborne troops who need lightweight gear. The Army tests the AR-1 in 1955 and finds some fairly serious problems with it. There are reliability issues, and also accuracy shortfalls. When the composite barrel heats up, differential stresses cause the point of impact to shift. This foreshadows the catastrophic failure of a composite barrel in AR-10 testing, but that is a story for another video. Ultimately after two rounds of testing the Army rejects the rifle, and that is pretty much the end of it. Armalite moves its focus to other projects, namely combining aircraft industry materials with the self-loading rifle of their other designer, Eugene Stoner. That, of course, will become the AR-10.

Since I know folks will ask, the AR projects between 1 and 10 were thus:

AR3: Stoner-type rifle in hunting configuration

AR5: Air Force survival rifle

AR9: Shotgun

The designations 2, 4, 6, 7, and 8 were set aside to drawing board projects that never materialized.

(more…)

October 21, 2025

The amazing invisible detail

Rex Krueger

Published 20 Oct 2025Patrons saw this video early: / rexkrueger

October 14, 2025

DSA’s Unique Titanium FAL Project

Forgotten Weapons

Published 28 May 2025DS Arms got some billet titanium and decided to make a batch of titanium receivers and other parts. This turned out to be a nightmarish amount of work, and two of the receivers had to be scrapped, leaving only 10 completed. They also made a number of other titanium parts, including flash hiders (which this rifle has) and gas blocks (which this one does not). Between the titanium and aluminum parts and the choice of a lightweight configuration, this FAL tips the scale at just UNDER 7.5 pounds (3.4kg). That is a very remarkable achievement, and does so without making sacrifices in durability or features. It is slightly sharper recoiling than a standard 50.00 FAL (which weighs almost 10 pounds / 4.5kg), but not uncomfortable at all — the recoil is less than I had expected.

Unfortunately DSA does not appear to have any plans to make addition titanium receivers, but this small batch serves as a very cool proof of concept!

(more…)

September 23, 2025

Learn EVERYTHING from Home Depot wood

Rex Krueger

Published 22 Sept 2025

September 15, 2025

When folks built their houses from Sears, Roebuck & Co. kits

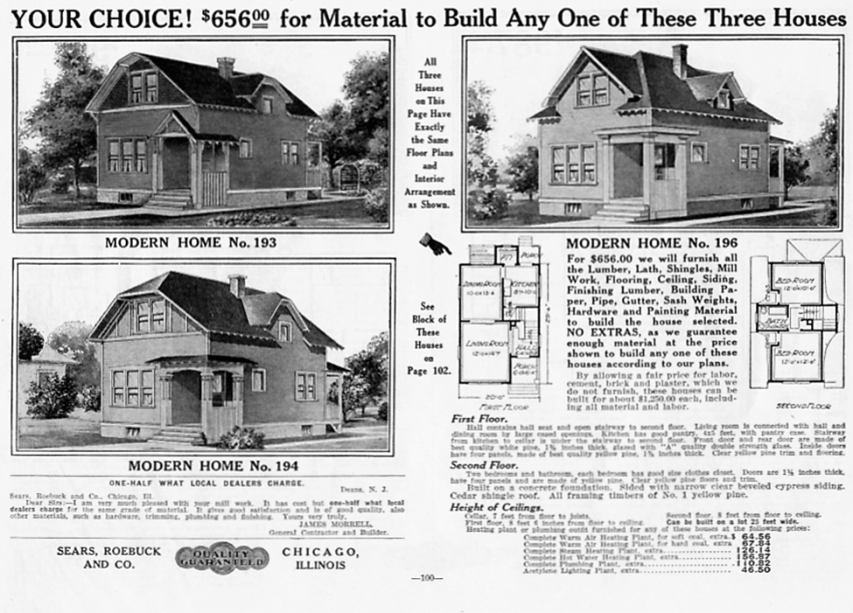

I thought I’d discussed the Sears kit homes about a decade back, but perhaps it wasn’t for the blog. Anyway, there’s a nice summary by Katrina Gulliver of how Sears and other companies made home-building great a century ago:

A hundred years ago, kit homes were more common in the US. Sold by Sears, Montgomery Ward, and other local firms, buyers received the plans and the pieces for a house and put it together themselves. Economies of scale made these a viable option for someone looking to build a house in the expanding suburbs.

The 1914 Sears Modern Homes catalog shows three homes that could each be bought for $656 (in the small print, they admit your outlay would be more like $1,250 all-in, including brick, cement, plaster — which they don’t supply — and labor). Your kit house would be delivered by rail; it was generally assumed householders would be handy enough (or know whom to hire) to put it all together from the supplied plans.

According to a 1930 report by the National Bureau of Economic Research, National Income and Its Purchasing Power, in 1914, the average clerk could be making $1,000, and a factory manager earning $2,300. That means these houses were within reach of lots of people — especially bearing in mind that land costs in many cities were also relatively low. In Chicago, lots within 5 miles of downtown were available for less than 50¢/square foot in 1914.

Those kit homes included wood, metal, and glass, and reflected both the tastes of consumers and the economies of bulk production. The various styles in the catalog over the years included craftsman, Dutch colonial, Federal, and cottage — styles that have continued to be popular in residential architecture of the US.

The Sears catalog of 1936 states: “This is the age of modern efficiency. No longer can human hands compete with machine precision and production. ‘Speed with accuracy’ is the watchword in any department of our great factories.”

(For those curious about such houses, fans of Sears kit homes put together lists of examples still standing.)

September 5, 2025

September 1, 2025

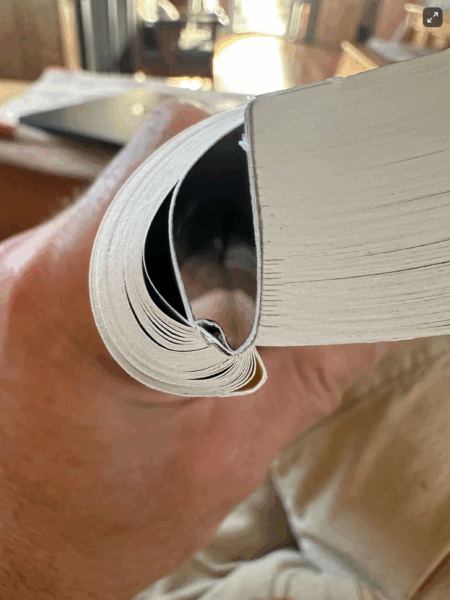

“… these two [books] are ‘perfect bound’, which is a misleading name for a crappy technique”

Chris Schwarz on the frustrations of a (physical) book reader with far too many modern printed books:

I don’t read much for pleasure these days. I spend about three hours a day reading manuscripts, draft blog entries, old woodworking texts, academic papers and contracts. When the workday is done, the last thing I want is someone else’s voice chattering in my head.

But I love books and have always been a voracious reader. So I keep a stack of books that I probe and pick at, like a 5-year-old forking through chop suey, looking for something to consume.

This month has been great. I’m in the middle of “The Overstory” by Richard Powers and “A Swim in a Pond in the Rain” by George Saunders. Both books were written with an exquisite pen, and I lose track of time when I’m reading them.

But both books also make me want to burn down the headquarters of Norton and Random House publishing. Because both books are made like dogshit.

Like most books these days, these two are “perfect bound”, which is a misleading name for a crappy technique. Like if we called a “butt joint” the “excellent end-grain joint,” or if we called miters the “super slanty joint”.

What’s perfect binding? Take a stack of individual sheets of paper, like the stack of pages you put in your printer. Slather some glue on one edge and press the goo into the pages. While the glue is still wet, slap the book’s cover to the glue on the spine. Trim the pages, sell the book and make an obscene amount of money.

I don’t know a binding technique that is crappier than perfect binding. Even loose-leaf pages in a Trapper Keeper are better because they can be repaired.

Perfect-bound books are – like a Ryobi drill – a product that has an expiration date. After two or three readings, the pages will start to fall out of the glue. You don’t even have to mistreat the binding for this to happen. The glue gets brittle, then you turn a page like a normal person and the leaves fall like it’s autumn.

Do not fool yourself and think that book publishers are suffering and need to cut corners in the manufacturing department. They aren’t. Book publishing is still one of the most profitable businesses, as far as margin is concerned. It’s not unusual for a publisher to have margins of 30 to 35 percent. (Note: Lost Art Press keeps a margin of about 15 percent – much lower because we pay more in royalties and pay a lot more for manufacturing.)

My paperback copy of “The Overstory” is the 23rd printing of the title since it was released in 2018. Norton is literally printing money at this point with the book. The book’s retail is $18.95. Manufacturing cost (at a plant in the United States): I’d guess is about $3.80.

Norton can do better. But it doesn’t have to. Customers are happy to pay $18.95 for an impermanent book.

August 1, 2025

How to make flat boards straight, smooth and square (stock preparation part 2) | Paul Sellers

Paul Sellers

Published 28 Jul 2013In this video Paul Sellers shows how to prepare a flat smooth board from rough stock. He does this with winding sticks and a no. 4 plane.

Part 1 is here: How to make square stock straight, sm…

Someone asked about the can Paul uses to lubricate the sole of the plane. You can find out how to make one here: http://paulsellers.com/2011/10/recycl…

To find out more about Paul Sellers and the projects he is involved with visit http://paulsellers.com

June 2, 2025

How to Repair & Rebind a Damaged Paperback as a Hardcover Book

Annesi Bindings

Published 14 Mar 2021This video walks you through the process of repairing a damaged paperback and rebinding it as a hardcover book. It is intended for complete beginners and shows you how to take the book apart, repair torn pages, re-glue it using the double fan method, insert cords into the spine, rebind it as a hardcover book, and reattach the original covers.

(more…)

May 18, 2025

QotD: Processing raw wool to make woollen cloth

Now when we left our wool it had just been shorn from our sheep. It is however, raw, oily from being on the sheep, likely still somewhat dirty, of uneven grades and types and also of course contains the other two fibers in the fleece (hair and kemp) which need to be removed before it can be used. The various processes used to get wool ready for spinning (or for sale) were sometimes collectively called “dressing” and involved various methods of sorting, scouring, combing, and washing.

The first step is sorting, dividing the raw wool into grades and types based on any number of factors, including fiber length, color, texture, crimp, strength, ability to take dye and so on. Different parts of the sheep produce wool with somewhat different qualities in this regard, but there are also differences based on the sex of the sheep, their health, age, diet, and for ewes whether they have had lambs. In order to get the best results in spinning (or the best value in selling) it is necessary to separate these grades out, grouping like wool with like. Too much mixing of fiber quality can make the end-product textile patchy in color, texture and its ability to take dye (the last one being quite visible, of course) and is to be avoided. This sorting was generally done by hand.

At this point, with the wool sorted, it could be sold, or further processed. The key question at this point was if the wool was to be washed or scoured (it would be combed or carded in either case, but this decision generally has to be made at this point). Scouring removes the lanolin (an oil secreted by the sheep which effectively waterproofs their wool) and other impurities. Leaving the lanolin in the wool can help with the spinning process and also to preserve the wool, but if the wool is to be dyed before being spun (for instance, if it is to be made into colored yarn rather than dyed as a whole fabric after weaving), it must be washed (or the lanolin will prevent the dye from sticking). Scouring could also be useful for wool that was going to be transported; in some cases the lanolin and other impurities might amount for up to 40% of the total weight of the raw wool (Gleba, op. cit. 98).

Practices in this regard clearly differed. In Greece, wool seems often to have been spun unwashed and women might use an epinetron, a ceramic thigh-protector, to keep the grease of the wool roving off of their clothes. On the flip side, both Varro (Rust 2.2.18) and Columella (De Rust. 11.35) assume that wool is generally to be washed (though they are thinking of wool being sold by large estates for commercial purposes and thus may have dyeing in mind). J.S. Lee notes that in medieval England wools with longer staples (that is, that forms into longer clusters or locks of fibers) were unscoured while short staple wools (which might be used in knitting) were more likely to be scoured. Scouring might be done on a small scale in the home or on a larger scale by either producers (before sale) or by clothiers and other purchasers (before dyeing).

Pre-modern scouring generally meant bathing the wool in a solution of warm water along with some agent that would remove the lanolin and other greases and impurities. The most common scouring agent was urine, something that pre-modern communities had in abundance; the ammonia content of urine allows it to break up and wash away the greases in the wool. Alternately, in the ancient period, the soapwort was sometimes used, as soaking its leaves in water could create a form of soap. By the early modern period, potash might also be used for this purpose, but even in the 1500s, it seems that urine was the most commons scouring agent in England. The process is smelly but generally fairly simple: the wool is allowed to sit in a solution of the scouring agent (again, generally urine) and warm water. Scoured wool would need to be re-oiled after it was dried to lubricate and protect the wool; typically olive oil was used for this purpose (both during the ancient and early modern periods) although J.S. Lee notes (op. cit. 45) that in the earlier parts of the Middle Ages, butter might be used instead in parts of Europe where olive oil was difficult to obtain in quantity.

Next, the wool has to be carded or combed, to remove any unusable or imperfect fibers or dirt, along with separating the strands by length and getting any tangles out before spinning. Let’s treat combing first, as it is the older of the two methods. Wool combs (in the ancient world, these were generally made of wood, bone or horn, but combs from the medieval period onward seem to generally be made with metal teeth projecting through a wooden handle) were used in pairs with the aid of a lubricant (grease, olive oil; these days there are specialty “combing oils”). One comb, the “moving comb” would be worked through the wool while the other comb which held the wool together was kept stationary, sometimes on the comber’s knee; in some cases it would secured to a fixed post (called a “combing stock”). You can see a demonstration of the basic method here.

Carding came later, though I have found no consensus on how much later. Gleba (Textile Production, 98) suggests that carding may have been in use in Italy by the end of the Roman period, while J.S. Lee (op. cit., 45) supposes carding to have been adopted into Europe via borrowing from the Islamic cotton industries of Sicily or Spain in the late 1200s. These suggestions are, of course, not mutually exclusive but I am hesitant to render a verdict between them. In any event, by late Middle Ages, carding is also a reasonably common processing method. Hand carders are generally wider, more paddle-like wooden boards with handles and pierced through by iron teeth; the earliest carders used teasel heads in place of the iron teeth (and the word “card” here actually comes from Latin, carduus, meaning thistle, referring to the use of teasel heads). Like combs they are used in pairs, with the wool placed on one, often held on the thigh, and then the other carder is drawn over the first until the wool is ready for spinning. You can see a demonstration here, and a direct comparison of the two kinds of tools here.

Though obviously quite similar methods (albeit with different tools) the two methods produce importantly different results in a couple of different ways. Both methods will remove remaining hair or kemp along with dirt or other particles that aren’t wool. But combed fibers generally produced stronger yarns (as I understand it, this is partly because it doesn’t straighten them out so much, allowing them to better tangle together during spinning), but combing is also a bit more wasteful in material terms, as shorter fibers are discarded in the process. Consequently, once both processes were available, they might both be used (and still are by practitioners of traditional wool-working today, as the video links above show), with combing more often used for long-fibered wools and carding for short-fibered wools.

Bret Devereaux, “Collections: Clothing, How Did They Make It? Part II: Scouring in the Shire”, A Collection of Unmitigated Pedantry, 2021-03-12.