Rex Krueger

Published 20 Jul 2022Find the problems that can make wooden planes unusable. Find them BEFORE you buy.

(more…)

July 21, 2022

Hidden flaws in vintage wooden planes

July 20, 2022

The Myth of Rosie the Riveter – On the Homefront 016

World War Two

Published 19 Jul 2022With American men going off to fight the war, there are concerns about a labor shortage. Enter Rosie the Riveter. The women who answered the “We Can Do It” call and entered the factories. But did she really exist?

(more…)

July 3, 2022

Model 1907/15 Berthier: The WW1 Standard Infantry Rifle

Forgotten Weapons

Published 24 Jul 2017http://www.patreon.com/ForgottenWeapons

When World War One broke out in 1914, France mobilized millions of men into military service — and it became abundantly clear that a lot of new rifles would need to be manufactured. The 1886 Lebel was no longer in production and was a slow rifle to make in any case — but the 1907 Colonial Berthier was being produced already, and was a more efficient design as well. By late 1914, plans were underway to drastically increase Berthier rifle production.

A few changes were made to the 1907 pattern, mainly changing the front end to accept the standard 1886 Lebel bayonet (“Rosalie”). After the first 80,000 had been made, the bolt handle was also changed from the bent carbine style to a heavier duty straight type. With these changes made, the Modele 07/15 was ready for mass adoption by the infantry, where it would serve side by side with the Lebel.

The primary manufacturer of 07/15 rifles was the St. Etienne arsenal, which build between 1.0 and 1.2 million of them by the spring of 1917. The Chatellerault arsenal produced another 436,000, and the Delauney Belleville automobile factory retooled its workshops to make rifles, producing another 170,000 of them. The Remington company in the US also took a contract to make 250,000 Berthier rifles, but was unable to meet the terms of the contract. Remington had taken on more wartime production work than it could handle, and failed to meet French quality and scheduling requirements. In August of 1916 that contract was cancelled, with just 9,440 rifles sent to France for use. The remaining 5,000-10,000 that had been made by Remington were sold on the commercial market in the US.

By 1916, it was clear that the 3-round capacity of the Berthier was a very real disadvantage (both tactically and psychologically) to the German Mauser rifles, and an upgrade program was put underway. This would ultimately become the 1916 pattern and would go into production in 1917.

If you enjoy Forgotten Weapons, check out its sister channel, InRangeTV! http://www.youtube.com/InRangeTVShow

April 10, 2022

March 28, 2022

QotD: The evolution of tanks through World War 2

One interesting thing about tank evolution that never gets mentioned in America is just how good the Soviets were at making tanks. The Germans are always assumed to have been the great tank builders, followed by the Americans, but it was the Russians who dominated the field in the tank game. Russian tanks were fast, powerful and easy to operate by their crews. Most important, they were reliable in all weather. The Russians assumed they would be fighting in horrible conditions and built a tank for it.

The Germans, in contrast, made one error after another when it came to tank design and tank building. They were obsessed with coming up with the biggest, most powerful tank, rather than making lots of good enough tanks. The result was lots of innovative designs, but most were failures and there was never enough of them. The Panzer IV was a very good tank with a platform that was flexible, but the Germans kept trying to come up with a super tank, rather than make lots of these. That was a costly error.

The American tank, which was used by the British, was not a great tank, but they were cheap and reliable, which meant there were loads of them. It was also a flexible platform for all sorts of other uses. The Sherman tank was about using the two advantages the Americans had over the Germans. One was more industry and the other was more soldiers. The plan was to beat the Germans with volume. While it would take five Sherman tanks to take out a German tank, that was math that worked in favor of the Americans.

This conflict between the perfect and the good enough showed up in many places during the war. The Germans seemed to look at the whole thing as an engineering project. The first step was to accept the restraints and then solve for the variables. The Russian and American view was always to limit the constraints and thereby increase the number of possible right answers. The Germans had much better human capital, but their opponents always had many more choices. They also had numbers, which counts for a lot.

The Z Man, “Tanking It”, The Z Blog, 2019-03-01.

February 27, 2022

Who is Springfield Armory? A Tale of Two Entities

Forgotten Weapons

Published 20 Feb 2018Today we will take a look at the history of Springfield Armory – both the American national arsenal founded in the 1770s and the commercial entity founded in the 1970s.

http://www.patreon.com/ForgottenWeapons

Cool Forgotten Weapons merch! http://shop.bbtv.com/collections/forg…

If you enjoy Forgotten Weapons, check out its sister channel, InRangeTV! http://www.youtube.com/InRangeTVShow

February 9, 2022

A Tour of Chapuis Armes: Home of the MR-73 Revolver

Forgotten Weapons

Published 5 Oct 2021http://www.patreon.com/ForgottenWeapons

https://www.floatplane.com/channel/Fo…

Cool Forgotten Weapons merch! http://shop.forgottenweapons.com

With the MR-73 revolvers finally becoming regularly available in the US, I figured it would be really interesting to see how they are made! So, I headed over to Chapuis Armes, where the Directeur Général, Vincent Chapuis, gave me a really nice tour. Want to see? Let’s go in …

Contact:

Forgotten Weapons

6281 N. Oracle 36270

Tucson, AZ 85740

January 30, 2022

Engineer’s Delight: Stemple 76/45 Becomes the Stemple Takedown Gun

Forgotten Weapons

Published 17 Sep 2021http://www.patreon.com/ForgottenWeapons

https://www.floatplane.com/channel/Fo…

Cool Forgotten Weapons merch! http://shop.forgottenweapons.com

The saga of how the original Stemple 76/45 became the Stemple Takedown Gun is a fantastic story of engineering design choices.

Essentially, John Stemple began by building a rather crude copy of the Swedish K in .45 ACP in the mid 1980s, called the Stemple 76/45. He produced and registered 2,000 transferrable receivers for the gun (pre-1986), but only built them slowly, a few at a time. In the late 1980s he faced criminal charges from ATF, and transferred the receivers to a friend while he (successfully) fought the charges. When he went to get the receivers back, his friend refused, and the two entered into a nearly decade-long legal battle over them.

By the time Stemple eventually won the case, he recovered about 900 transferrable tubes. By this time (circa 2000) these tube receivers were much more valuable than when he first made them, as the machine gun registry was closed in 1986 and new ones can no longer be made. At this point, Stemple reached out to Brian Poling (BRP Corp) to act as a subcontractor to make the parts for the Stemple 76/45. But Poling had a better idea …

Poling’s thought was to instead design a new gun that would be much more desirable as a recreational gun than the 76/45. He envisioned something controllable, low recoil, and using large drum magazines. Such a gun would be a lot more fun at the range than the MACs and Uzis that tended to dominate the submachine gun market at the time. In addition, Poling’s gun would be designed specifically to protect the irreplaceable registered receiver tubes from wear or damage. The result was the STG-76 — the Stemple Takedown Gun.

In order to remain legal, the STG-76 had to leave the original 76/45 receiver tube cutouts unmodified, so as not to change the configuration of the receiver itself. Poling designed a replaceable internal trunnion and slip-over magazine well, allowing multiple different calibers and magazine configurations. The internals were closely based on the Finnish kp31 Suomi, for which parts kits became readily available in the early 2000s. This also facilitated the use of Suomi 71-round drum magazines. The original STF-76 design also included a bipod for easy shooting, and a grip and stock from an HK91 or CETME Model C for comfortable handling (instead of the terrible metal strut stocks common to most budget SMGs).

Several other interesting configurations would follow (stay tuned for those videos), and the guns remain available brand new to this day. The original supply of receivers is sufficient for production until about 2023 …

Contact:

Forgotten Weapons

6281 N. Oracle 36270

Tucson, AZ 85740

January 27, 2022

QotD: American cars after 1970

If you weren’t there, I don’t think I can adequately convey to you just how bad American products were back in the Seventies and Eighties.

Especially cars. American-made cars were almost Soviet, in that if you happened to get one made by the one factory the one day the workers weren’t falling down drunk on the job, it might run … for a while. American workers weren’t drunk, of course, but they were unionized, which from a quality control perspective amounted to the same thing. Chrysler and especially General Motors were little more than employee pension plans that occasionally cranked out a crappy car. Not to take anything away from underhanded Japanese business practices back then — “dumping” etc. — but you had to give the Nips this, their shitboxes actually worked.

Even ten-thumbs guys like me became at least semi-adequate shade tree mechanics, because we had to keep the Sixties hand-me-down cars that got us through college running well into the 1990s, or we’d have to walk. No one in his right mind bought an American-made car from any year after 1970. Take that out for any large consumer product, and there you had it. Thanks, Big Labor!

But here in Clown World, the dilithium crystals have reversed polarity, so what was already fake and gay back at the very dawn of the Fake and Gay Era (future historians, please credit me for that coinage in your textbooks) is now a pillar of probity. The enemy of my enemy is my friend, and Big Labor is definitely shaping up to be the enemy of Big Government. Brandon’s puppetmasters have clearly decided to go for the quadruple axel, politically — they’re going to totally alienate every single cisgender, heteronormative member of their old coalition, so that when they finally make Utopia with just Intersectional Genderfluids of Color, even the French judge will be forced to give them a 10.

It’s a bold strategy, Cotton … let’s see how it works out for them. In the meantime, yeah, if you’ve got a tradesmen’s local in your area, buy ’em a box of donuts or something. They’re fighting the good fight on this one.

Severian, “Friday, No Job, Etc.”, Founding Questions, 2021-10-22.

January 13, 2022

How A Village Keeps India’s Handmade Shuttlecock Industry Alive | Still Standing

Business Insider

Published 10 Sep 2021Jadurberia village is the shuttlecock capital of India where workers have been making badminton birdies for generations. But the rise of mechanized assembly lines and the popularity of synthetic shuttlecocks are threatening to shut down small factories like the Niyogi family’s Dodo Shuttles.

For more information, visit http://www.dodoshuttles.com/.

——————————————————

#Shuttlecock #StillStanding #BusinessInsider

Business Insider tells you all you need to know about business, finance, tech, retail, and more.

Visit us at: https://www.businessinsider.com

BI on Instagram: https://read.bi/2Q2D29T

BI on Twitter: https://read.bi/2xCnzGF

BI on Amazon Prime: http://read.bi/PrimeVideoHow A Village Keeps India’s Handmade Shuttlecock Industry Alive | Still Standing

December 29, 2021

War in Numbers 1942 – WW2 Special

World War Two

Published 28 Dec 2021Quantity had a quality of its own. 1942 was the year in which the dimensions of the Second World War became truly apparent. The US and its unmatched economic power began to outproduce any other warring nation, manufacturing a fleet of ships and aircraft in record time. In the east Soviet industry began recovering itself, producing tens of thousands of tanks despite tremendous losses. All the while the German logistic system got overwhelmed by the vastness of the occupied territory.

(more…)

December 15, 2021

Is the Wehrmacht Defeated in 1942? – WW2 Special

World War Two

Published 14 Dec 2021It’s late 1942 and the German Army is close to ruin. The Ostheer alone has suffered more than a million casualties in its fight against the Red Army. If the Wehrmacht cannot find a way to return to its former strength or reap decisive strategic benefits in the near future, it will ultimately face destruction in a war of attrition.

(more…)

December 8, 2021

SA80 History: The Pre-Production XL85 and XL86

Forgotten Weapons

Published 17 May 2017Armament Research Services (ARES) is a specialist technical intelligence consultancy, offering expertise and analysis to a range of government and non-government entities in the arms and munitions field. For detailed photos of the guns in this video, don’t miss the ARES companion blog post:

http://armamentresearch.com/british-e…

The SA80 saga continues today with the final pre-production versions of the L85A1 and L86A1, although at this point they still both carry XL designations, as they were not yet formally adopted weapons. In these weapons we can see a couple last distinctive mechanical changes, but perhaps more importantly by this time the worker morale at RSAF Enfield was thoroughly in the tank. It had become well known that the factory complex was going to be taken public or sold outright, and it was widely expected that Enfield would be shut down as a result. A new facility would be built in Nottingham, but none of the rank and file staff expected to transfer. They would be laid off, and they knew it. Not surprisingly, quality control suffered as a result.

As for the guns themselves, the first distinctive visible improvement was in the magazine well. In the XL70 weapons, the bottom half of the magazine well had been simple welded onto the bottom of the lower receiver, in order to retain the easy stamping of that element. On these guns, that have been replaced by a separate box which encompassed the magazine and was spot welded into the lower receiver. This change in construction method allow the magazine well to be much more precisely located in the receiver, and then fixed in place without the risk of warping the thin sheet metal of the lower receiver – while still retaining the simple stamping of that lower.

The other visible change was to the Light Support Weapon, and it consisted of a long “girder” support added below the barrel. This was intended to mount the bipod onto, in the hopes of resolving the long-running problem of split groups in the LSW. This was a problem in which the first round of a burst would hit substantially low and left relative to the rest of the burst. While the LSW was a quite accurate weapon in semiautomatic mode, this split group problem was a substantial detriment to its effectiveness as a proper support weapon.

http://www.patreon.com/ForgottenWeapons

Cool Forgotten Weapons merch! http://shop.bbtv.com/collections/forg…

If you enjoy Forgotten Weapons, check out its sister channel, InRangeTV! http://www.youtube.com/InRangeTVShow

December 5, 2021

Will publishers move back to actually printing their own books?

In the latest SHuSH newsletter, Kenneth Whyte explains some of the issues publishers face in getting their books printed, as most publishers outsourced the actual physical work of printing and binding many years back:

I had a serious conversation with another publisher this week about the need for publishers to start printing their own books.

Those familiar with publishing history will know that from the fifteenth to the nineteenth century, most publishers printed their own books. Ownership of a press, as much as anything, was what made a publisher a publisher. In the course of the twentieth century, it was decided that publishing books and printing books were different businesses. Virtually all publishers outsourced their printing to high-volume printing specialists who were constantly upgrading their equipment, and who, theoretically, at least, were better, faster, and cheaper than in-house printing operations.

[…]

Apart from that handful of artisans, today’s book publisher can no more operate a printing press than a backhoe. He or she outsources printing to specialists on a project-by-project basis.

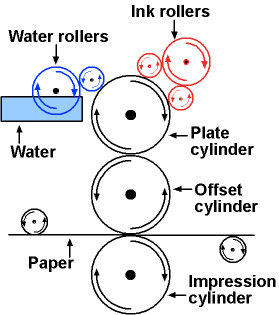

The options for large-scale quality printing are increasingly scarce, thanks to a lot of consolidation in the printing business. Smaller shops (like the artisans) only do paperbacks; hardcovers require a lot of expensive binding equipment. If a publisher wants a big run of a hardcover title, the most likely printers are the industry giants: R.R. Donnelley (above) or CJK Group in the US; Friesens and Marquis in Canada. These companies all use huge offset web presses that are big as gymnasiums and only economically efficient at higher quantities (i.e., in the thousands). The technology involves metal plates and rubber mats and massive rolls of paper (if you’re interested, read more here) and the quality is first rate.

I should have said that the only options for a big run of hardcovers in Canada are Friesens in Altona, Manitoba and Marquis in Montmagny, Quebec. There are no hardcover printing options in Ontario, where so many publishers are concentrated (although Marquis does have a plant in Toronto).

[…]

The reason publishers are now talking about doing their own printing is that it is increasingly difficult to get time on any kind of press. Friesens, when Sutherland House started a few years ago, could usually do a job for us in eight weeks. There were seasons — the dead of winter, the height of summer — when they could deliver even faster and we’d get a discount because their presses weren’t especially busy. COVID-19 changed all that.

People have been buying more books during the pandemic, and publishers have been printing more. Friesens is now fully booked six to eight months out; its fall 2022 schedule is already crowded. The US printers we use as alternatives to Friesens are similarly backed up.

It’s making the decision to print in hardcover hazardous. It used to be that if you printed a few thousand copies of a new book in hardcover and it was in danger of selling out, you could get back on press in six to eight weeks, maybe less, and continue to fill orders. Now, if that original press run is selling fast, you might have to wait six to eight months to print a second edition. You’ll be out-of-print for most of that time, and all momentum will be lost. Some publishers are thus moving immediately to digital paperback formats (none of the digital printers have hardcover binderies) for their second editions, even if it’s only weeks into a book’s life. There is more availability at digital printers, so resorting to the digital paperback format allows you to keep your momentum.

November 25, 2021

Why The Most Expensive US Martial Pistol Exploded A Lot

Forgotten Weapons

Published 12 Aug 2021http://www.patreon.com/ForgottenWeapons

https://www.floatplane.com/channel/Fo…

Cool Forgotten Weapons merch! http://shop.forgottenweapons.com

The Colt Model 1847 Walker is one of the most valuable of all US military handguns in the collecting community, with examples sometimes breaking seven figures. However, the Walker was in many ways a remarkable failure as a service sidearm, mostly because it tended to explode. By today’s standards, it exploded quite a lot.

Why?

Basically, a combination of several factors:

– The Walker was made of wrought iron, and not always the best quality wrought iron. Cylinders had internal flaws that became weak points and failed upon firing.

– The Walker had a huge powder capacity in its chambers, between 50 and 60 grains depending on the projectile used. This was basically rifle size, and it left the cylinder design with a very small margin of safety.

– Powder composition and grain size was less standardized in the 1840s than it is today, making overpressure loads more likely than today.

– The Walker was designed for a conical “Pickett” bullet that was tricky to load correctly (point forward). Loading it backward could increase the powder volume in a chamber.Of nearly 400 Walkers issued for the Mexican-American War, only 191 were returned after a year’s service, and only 82 of those were serviceable. Some of those missing guns were lost and stolen, but a substantial number — generally accepted to be 20%-30% — suffered burst barrels, burst cylinders, and broken cylinder arbors. Whoops!

Contact:

Forgotten Weapons

6281 N. Oracle 36270

Tucson, AZ 85740