It bears repeating that the ’60s — not the ’50s, and certainly not the ’70s — were Detroit’s golden age. The age of tailfins and bulbous deco car bodies was over, and designers went about the business of making the cars look as fast as their increasingly powerful engines actually made them go. The zenith of this is probably the Mustang, but its design aesthetic — less chrome, long lines, agonizing thought put into key details like the grille and the silhouette — dominated the industry, resulting in a decade of cars that look like they want to be driven, not parked (the ’50s) or rolled off cliffs (the ’70s.)

Rick McGinnis, “Fury”, Zero to Sixty, 2012-09-10

September 12, 2012

QotD: Detroit’s golden age

August 31, 2012

Innovative ways to use huge surplus of beetle-blighted lumber

British Columbia has a problem with their trees: too many of them are dead due to a massive increase in the population of the mountain pine beetle. The province is searching for ways to cope with the lumber from all the beetle-killed trees:

When life hands you lemons, goes the old saw, make lemonade. But what if life should hand you 18m hectares (44m acres) of dead trees? That is the problem faced by the province of British Columbia in Canada, which could lose over half its pine trees to the depredations of the fearsome mountain pine beetle. The beetle, no bigger than a grain of rice, is native to the forests of Western North America, where it kills trees by releasing a blue stain fungus that prevents the flow of water and nutrients. While the insect was historically kept in check by spells of cold weather, years of mild winters have unleashed an outbreak whose spread and severity is unlike anything seen previously.

As a result, the province is peppered with billions of dead, grey trees. If they are simply left standing, they will eventually either decay or burn in forest fires. In either case, they will release the carbon dioxide they stored while growing, swelling Canada’s total carbon footprint from 2000 to 2020 by 2%.

[. . .]

Canadian researchers have discovered other uses for BKP. Sorin Pasca, a graduate student at the University of Northern British Columbia, found that rain and snow conveniently wash out sugars and other organic compounds from dead pine trees. By grinding up the dry BKP and adding it to normal cement, he created a hybrid material that is waterproof, fire-resistant and pourable like concrete but that can be worked, cut and nailed or drilled like wood. The material, dubbed Beetlecrete, has already been used to make countertops, benches and planters.

Even more esoteric uses for BKP are on the table. Nanocrystalline cellulose, made up of microscopic needle-like fibres, is a lightweight, ultra-rigid material that can be extracted from wood pulp. Currently used to improve the durability of paints and varnishes, nanocrystalline cellulose promises strong, iridescent films that may find uses in industries ranging from optical computing to cosmetics. And, as a last resort, dead and fallen pine trees can feed British Columbia’s 800MW of bio-mass power plants, which burn pellets of BKP and other waste wood to generate electricity.

August 20, 2012

Royal Navy announces design of new “Type 26 Global Combat Ship”

Britain’s Royal Navy revealed the design of the Type 26 today:

The announcement on the Type 26 Global Combat Ship has been described by officials as a “significant milestone” in a programme which will support “thousands of UK shipbuilding jobs”.

Basic specification images show sleek stealth features, familiar to modern warships, making them harder to detect.

The ship will be 148 metres long with a displacement of 5,400 tonnes.

The MoD has been working with BAE Systems since 2010 to determine the basic design for the ship. Detailed specifications of the vessel will now be examined.

Vertical missile silos for a range of weapons, such as cruise missiles, will be housed on board along with a medium calibre gun.

The hangar on board will house a Merlin or Wildcat helicopter and there will be extra space for unmanned drones, underwater vehicles or other specialist equipment.

[. . .]

The current plan is to build 13 of the ships, which are due to start coming into service after 2020.

The Type 26 will replace the 13 Type 23 frigates but the MoD is not giving a precise commitment on numbers until they know the unit cost.

The First Sea Lord, Admiral Sir Mark Stanhope, says the ship will be used “across the full spectrum of warfare”.

He added: “The T26 GCS will be a multi-mission warship designed for joint and multinational operations… including complex combat operations, maritime security operations such as counter piracy, as well as humanitarian and disaster relief work around the world.”

The US Navy’s still-experimental Littoral Combat Ship

New ship designs are highly complex and often take years to debug. The US Navy’s Littoral Combat Ship (LCS) program surprised most observers by settling on two different designs and splitting the intended order quantity between the two design firms. One of each design is in service now, the more traditional USS Freedom (LCS-1), and the trimaran-hull USS Independence (LCS-2). Each has had its own set of teething problems:

The LCS has long been a good source of bad news and potentially explosive revelations. In the last year the LCS design has been found to have structural and other flaws. The first LCS, the monohull USS Freedom, has suffered four major problems since it entered service four years ago. The latest one is a leak in a propeller shaft seal, which caused some minor flooding. Despite this Freedom was able to get back to port under its own power. Last year cracks in the hull as long as 17 cm (6.5 inches) were discovered, and the water-jet propulsion system broke down as well. Two years ago one of the gas turbine engines broke down.

The most serious problem is in the USS Independence, a radical trimaran design. It seems that a “dissimilar metals” situation arose when salt water, the aluminum hull, and some other metals got into close proximity with each other and extensive corrosion resulted. Aluminum hulls tend to corrode more than steel, but the problem became so bad with the USS Independence that, 18 months after entering service, it was sent into dry dock for corrosion repairs and design changes to eliminate the problem.

Cracks, corrosion, and equipment breakdowns are common in new warship designs especially designs that are radically different (like the broad trimaran shape of the USS Independence). Usually, these problems can be fixed but there’s always the risk that the new design will be seriously flawed, requiring extensive rework and a halt in building more ships of that class. So far, the U.S. Navy has not wavered in the face of potential design and construction flaws.

This is all part of the expected years of uncertainty and experimentation as this radical new combat ship design seeks to find out what works, to what degree, and what doesn’t. There is some nervousness about all this. The U.S. Navy has not introduced a radical new design for nearly a century. The last such new design was the aircraft carrier, which required two decades of experimentation and a major war to nail down what worked. Even the nuclear submarines of the late 1950s and early 60s were evolutionary compared to what the LCS is trying to do.

USS Freedom at sea. Click for full-sized image at Wikipedia

USS Independence at pier side. Click for full-sized image at Wikipedia.

August 19, 2012

ESR on the limits of “lawfare” for Apple

To put it mildly, ESR isn’t a fan of Apple’s lawfare approach to competition:

It’s beginning to look like Apple’s legal offensive against Android might backfire on it big-time. Comes the news that Judge Koh has declined to suppress evidence that Apple may have copied crucial elements of the iPad design from prototypes developed by Knight-Ridder and the University of Missouri in the mid-1990s.

Those of us aware enough of computing history to be aware of early work by XEROX PARC and others have always been aware that Apple’s claims of originality were highly dubious. Apple’s history is one of adroit marketing and a facility for stealing adapting ideas from others, wrapping them in admittedly excellent industrial design, and then pretending that all of it originated de novo from the Cupertino campus.

The pretense has always galled a little, especially when Apple’s marketing created a myth that, footling technical details aside, the whole package somehow sprang like Athena from Steve Jobs’s forehead. But it didn’t become intolerable until Apple began using lawfare to suppress its competition.

The trouble with this is that there’s actually a lot of prior art out there. I myself saw and handled a Sharp tablet anticipating important iPhone/iPad design tropes two years before the uPhone launch, back in 2005; the Danger hiptop (aka T-Mobile Sidekick) anticipated the iPhone’s leveraging of what we’d now call “cloud services” in 2002-2003; and of course there’s the the Sony design study from 2006, described by one of Apple’s own designers as an important influence.

If only Apple were honest about what it owed others…but that cannot be, because the company’s strategy has come to depend on using junk patents in attempts to lock competitors out of its markets.

June 11, 2012

An epitaph for the original Arts and Crafts movement

Colby Cosh has an interesting slant on William Morris and the original Arts and Crafts movement (for the record, I’m quite a fan of a lot of A&C artifacts, if not quite so much of their philosophy):

In the 19th century, William Morris preached a social revolution in which exploitative “useless toil” would be replaced by “useful work”. He dreamt of a world that would reject shoddy mass-produced goods in favour of objects made with care and craftsmanship. Any business that sells “artisanal” goods, whether the goods be curtains or crumpets, is essentially quoting Morris and referring to his promise.

That promise, of course, failed spectacularly. It did not even survive Morris’s own time. His “libertarian socialism” of crafted objects and honest work found itself drowned out at every turn by leftist alternatives which, more sensibly, accepted the power and inevitability of mass production. 20th-century Marxism wasn’t opposed to factories; it worshipped them, fetishized them. The fatal problem with Morris’s appeal is that he was just plain wrong about mass-produced objects necessarily being unlovely junk. We have been to Ikea; we know better.

Morris felt very strongly about this, and from his own historical standpoint, he was certainly on to something. It’s impossible for us to imagine what kind of things factories suppurated into the marketplace before things like statistical control charts were invented, or before items like micrometers were themselves mass-produced to a consistent high standard. Morris lived in a world where individual masons and cabinetmakers and weavers really were losing their livelihoods to a tide of undifferentiated, undistinguished banality; his feelings of alarm now seem fussy when we read him, but that is because only the better-made Victorian objects have physically survived destruction or disposal and reached our time.

Soon enough, however, the art of industrial design would come to the rescue. If Morris could have lived long enough to see the Studebaker Commander or the IBM Selectric II or, yes, the furshlugginer iPhone, he would have packed in the Arts and Crafts talk and gone straight to work designing pickle-jar labels. (Morris was not too consistent when it came to the ultimate logical consequences of a world made by hand, anyway. The influential Kelmscott Press he founded in 1891 favoured early printing techniques and letterforms, but it was, at any rate, a press; unlike his spiritual ancestor William Blake, he didn’t set out to mimic the appearance of illuminated manuscripts by the actual method implied in the etymology of the term “manuscript”.)

While I picked this section of the article to quote, you really should read the whole thing. It’s some of the most thought-provoking writing I’ve seen in months.

April 22, 2012

Danish Dutch design helps rescue the US Coast Guard from further embarrassment

Strategy Page on the US Coast Guard’s latest cutters:

The U.S. Coast Guard recently commissioned the first of 58 “Fast Response Cutters.” These are 46.8 meter (154 feet) long, 353 ton vessels equipped with a 8 meter (25 foot) rigid hull boat launched and recovered internally from a ramp in the stern (rear) of the ship. Armament of the cutter (as seagoing coast guard ships are called) consists of a remotely controlled 25mm autocannon and four 12.7mm (.50 caliber) machine-guns, plus small arms. Top speed is 52 kilometers an hour and the crew of 22 has sleeping and eating facilities on board so the ship can be at sea five days at a time (and 2,500 hours, or over 100 days, a year at sea). The Fast Response Cutter is basically a slightly larger version of the

DanishDutch Damen Stan 4207 patrol vessel.The

DanishDutch design was selected four years ago because, a year before the Coast Guard was finally forced to admit defeat in its effort to build an earlier design for 58 new patrol ships (Fast Response Cutters.) The ship builders (Lockheed Martin and Northrop Grumman) screwed up, big time. While the Coast Guard shares some of the blame, for coming up with new concepts that didn’t work out, the shipbuilders are the primary culprits because they are, well, the shipbuilding professionals, and signed off on the Coast Guard concepts. Under intense pressure from media, politicians and the shame of it all the Coast Guard promptly went looking for an existing (off-the-shelf) design, and in a hurry. That’s become urgent because of an earlier screw up.Six years ago, the Coast Guard discovered that a ship upgrade program made the modified ships structurally unsound and subject to breaking up in heavy seas

Update: Thanks to eagle-eyed commenter Guan Yang who pointed out that the design is actually Dutch, not Danish. I’ve modified the quoted text to match the correct information.

August 24, 2011

Replacing “Lorem Ipsum”

You’ve probably encountered bits of Latin placeholder text on web pages, generally known as “Lorem Ipsum”, from the first words of the original. If you’re looking for something a bit edgier, you might try Samuel L. Ipsum instead:

Of course, I wouldn’t recommend actually using this unless you’re doing work for customers who wouldn’t be offended when it — inevitably — slips past the design phase and shows up in the finished product.

June 6, 2011

Tyler Cowen discusses “The Great Stagnation”

May 24, 2011

Britain’s entry in the new race to space

Jonathan Amos reports on the UK Space Agency (UKSA) long-simmered design/proposal called Skylon:

Skylon has been in development in the UK in various guises for nearly 30 years.

It is an evolution of an idea first pursued by British Aerospace and Rolls Royce in the 1980s.

That concept, known as Hotol, did have technical weaknesses that eventually led the aerospace companies to end their involvement.

But the engineers behind the project continued to refine their thinking and they are now working independently on a much-updated vehicle in a company called Reaction Engines Limited (REL).

Realising the Sabre propulsion system is essential to the success of the project.

The engine would burn hydrogen and oxygen to provide thrust — but in the lower atmosphere this oxygen would be taken directly from the air.

This means the 84m-long spaceplane can fly lighter from the outset with a higher thrust-to-weight ratio, enabling it to make a single leap to orbit, rather than using and dumping propellant stages on the ascent — as is the case with current expendable rockets.

Update: Lewis Page has more on the Skylon project.

March 19, 2011

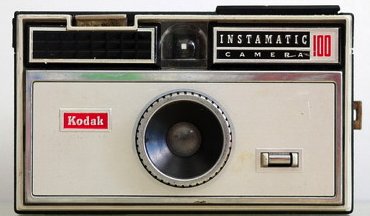

American Digest: This is why Kodak is withering away

Tell me that this simple idea has never occurred to anyone at Kodak:

If the company that calls itself Kodak today had a brain, it would copy the “Instamatic 100” from Kodak’s greatest hits, drop a first rate lens in it, add some great chips, a view screen as big as the back of the camera, and rebrand it as the “Kodak Digimatic 100.” Instant win.

They’ll never be cool enough to do it. Somewhere in the 1990s, Kodak lost the ability to design and innovate. Once the king of the camera world, Kodak’s now just the place where bad designs and worse marketing go to die. Today, Kodak needs a brain the same way Scarecrow needed one in the first reel of “Wizard of Oz.” Like Scarecrow, there’s a long brick road awinding into the land of its dreams.

It wasn’t always that way. There was a time when it seemed that everyone in America owned an Instamatic. It was a camera that, in its simplicity, elegance and rock-bottom cost, was an icon of its age

Of course, doing it now would be far too late: this was a winning strategy for 2001, not 2011. If they do it now, it’ll flop because they’ve squandered all the immense goodwill that used to be associated with the company name. It was the “everyman” camera and film: professionals had their specialized cameras and even more specialized film, but everyone else just bought Kodak. Kodak was “good enough”, dependable, predictable.

It takes immense lack of talent to fumble that much potential so thoroughly and so consistently. Almost a genius level of anti-talent at the corporate level.

March 15, 2011

A new way of looking at wood flooring

To state the obvious, trees don’t grow in nice straight lines. As natural creatures, they bend and sway in their environment — if they didn’t, they wouldn’t be able to withstand the extremes of weather. While this is great for the tree, once the tree has been cut down, the amount of useful wood that can be harvested is limited by many factors, including just how far from “straight” the trunk of the tree grew. Much of the wood that can’t be economically used for solid wood products ends up as chips, flakes, or fibres for manufactured “wood” products.

Bolefloors may increase the amount of solid wood that can be used for flooring:

Bolefloor technology combines wood scanning systems, tailor-made CAD/CAM developments and innovative optimization algorithms for placement software developed by a Finnish engineering automation company and three software companies in cooperation with the Institute of Cybernetics at Tallinn University of Technology.

Bolefloor scanners’ natural-edge visual identification technology evaluates “imperfections” such as knots and sapwood near the edges or ends so that floors are both beautiful and durable.

H/T to BoingBoing for the link.

March 14, 2011

Analysis of the Fukushima reactor situation

Lewis Page sees the triple-whammy disaster that hit the Fukushima nuclear plant as proof of the design:

Let’s recap on what’s happened so far. The earthquake which hit on Friday was terrifically powerful, shaking the entire planet on its axis and jolting the whole of Japan several feet sideways. At 8.9 on the Richter scale, it was some five times stronger than the older Fukushima plants had been designed to cope with.

If nuclear powerplants were merely as safe as they are advertised to be, there should have been a major failure right then. As the hot cores ceased to be cooled by the water which is used to extract power from them, control rods would have remained withdrawn and a runaway chain reaction could have ensued — probably resulting in the worst thing that can happen to a properly designed nuclear reactor: a core meltdown in which the superhot fuel rods actually melt and slag down the whole core into a blob of molten metal. In this case the only thing to do is seal up the containment and wait: no radiation disaster will take place, but the reactor is a total writeoff and cooling the core off will be difficult and take a long time. Eventual cleanup will be protracted and expensive.

In fact, though the quake was far beyond design limits, all the reactors went into automatic shutdown perfectly: triumph number one. Control rods slammed into the cores, absorbing the neutrons spitting from the fuel rods and pinching off the uranium-fission chain reactions powering the plant.

[. . .]

For a few hours all was well. Then the tsunami — again, bigger than the plant had been built to cope with — struck, knocking out the diesel backups and the backup diesel backups.

Needless to say, this being a nuclear powerplant, there was another backup and this one worked despite having been through a beyond-spec quake and the tsunami. Battery power cut in and the cores continued to be cooled, giving the plant operators some hours of leeway to bring in mobile generators: triumph number three.

Unfortunately it appears that the devastation from the quake and tsunami was sufficient that mobile power wasn’t online at all the sites before the temperatures inside the cores began to climb seriously.

On the flip side, Colby Cosh finds the information sharing from the Japanese authorities to be less than helpful:

It’s a frustrating sequence of events to behold, and it has been made more so by the poor crisis management of the Tokyo Electric Power Co. (TEPCO) and the Japanese government. A serious nuclear incident is the whole world’s concern, and TEPCO and Japan have an obligation to explain to the world just what has happened. But English-language reports from the state broadcaster, NHK, have been shockingly feeble and confused. TEPCO’s press releases, meanwhile, are masterpieces of indecipherable technical and even legal jargon. (“As the reactor pressure suppression function was lost, at 5:22am, Mar 12th, it was determined that a specific incident stipulated in article 15, clause 1 has occurred.”)

The global public has been left to figure out for itself what to make of hazy videos of nuclear power facilities exploding. What little context we can assemble, as we try to interpret such a mortifying sight, arrives mostly in shreds provided by Western oracles — ones who, in their turn, seem to mostly be working from supposition and indirect evidence, and who may not be particularly independent from the nuclear industry.

No one should forget, while trying to make sense of what’s happening in Japan, that something like 300 people died in major coal mining accidents around the world in 2010 alone. None of those accidents involved natural disasters, and probably not all of them even involved culpable human error. We just accept a certain quantum of mortality as the cost of keeping the lights on — when it comes to every means of power generation, that is, except nukes. A death toll in the single digits from the Fukushima troubles would represent an amazing triumph of design robustness. (Especially if we judge the quality of Japanese engineers and regulators by their competence at communications.)

February 18, 2011

Ron Hickman, inventor of the ubiquitous Workmate

Many people have bought and used the Workmate collapsible workbench . . . 30 million or so. The inventor, Ron Hickman, Ron Hickman, died recently:

Hickman, who lived in Jersey, was 78. His design for the wood-and-steel foldable workbench and vice was rejected by several tool companies that believed the bench wouldn’t sell.

Tool company Stanley told him the device would sell in the dozens rather than hundreds, while other companies told him the design would not sell at the necessary price. It has since sold about 30 million units around the world, and 60,000 were sold in the UK last year alone.

Hickman sold the benches himself when he couldn’t find a backer through trade shows direct to professional builders. Black & Decker saw the light in 1973 and began producing them. By 1981 it had sold 10 million benches.

He came up with the design when he accidentally sawed through an expensive chair while making a wardrobe. He had been using the chair as a workbench.

His designing skill wasn’t limited to tools: he also is credited with the design of the Lotus Elan.