Practical Engineering

Published 1 Oct 2024Sand: a treatise …

There’s a lot changing in the construction industry, and a lot of growth in the need for materials like sand and gravel. But I don’t think it’s fair to say the world is running out of those materials. We’re just more aware of all the costs involved in procuring them, and hopefully taking more account for how they affect our future and the environment.

(more…)

January 18, 2025

Is the World Really Running Out of Sand?

November 24, 2024

QotD: Wood

If someone today invented wood, it would never be approved as a building material. It burns, it rots, it has different strength properties depending on its orientation, no two pieces are alike, and most cruelly of all, it expands and contracts based on the relative humidity around it. However, despite all of these problems, wood is the material of choice when building houses. In fact, we can use wood better than we can use steel, masonry and concrete.

Joseph Lstiburek, Builder’s Guide to Cold Climates, 2000.

August 29, 2024

How to Make a Ladle | Episode 1

Paul Sellers

Published Apr 26, 2024It may not be a large project, but creating a ladle from fully kiln-dried hardwoods like sycamore and maple differs from green, uncured wood. Tougher to carve yes, but there is no shrinkage and no risk of cracking through drying. It is a wonderful project for learning to work with multi-directional grain and to also use gouges and such.

This is a great beginner guide for those starting with gouge work.

——————–

(more…)

August 23, 2024

How to bind loose pages together: a simple method

Annesi Bindings

Published Mar 7, 2021This video demonstrates a very simple way of binding loose pages together. It is intended for people who have texts that they want to bind together, but who are looking for a better method than simply stapling, paper clips, or ring binding. The video is suitable for non-bookbinders and only requires minimal materials and PVA glue.

If you are looking for how to bind loose pages into a hardcover book, I demonstrate that in this video:

• How to Bind a Perfect-bound Book

August 17, 2024

QotD: Sheep and wool in the ancient and medieval world

Our second fiber, wool, as readers may already be aware, comes from sheep (although goat and horse-hair were used rarely for some applications; we’re going to stick to sheep’s wool here). The coat of a sheep (its fleece) has three kinds of fibers in it: wool, kemp and medullated fibers. Kemp fibers are fairly weak and brittle and won’t accept dye and so are generally undesirable, although some amount of kemp may end up in wool yarn. Likewise, medullated fibers are essentially hair (rather than wool) and lack elasticity. But the wool itself, composed mostly of the protein keratin along with some lipids, is crimped (meaning the fibers are not straight but very bendy, which is very valuable for making fine yarns) and it is also elastic. There are reasons for certain applications to want to leave some of the kemp in a wool yarn that we’ll get to later, but for the most part it is the actual wool fibers that are desirable.

Sheep themselves probably descend from the wild mouflon (Ovis orientalis) native to a belt of uplands bending over the northern edge of the fertile crescent from eastern Turkey through Armenia and Azerbaijan to Iran. The fleeces of these early sheep would have been mostly hair and kemp rather than wool, but by the 4th millennium BC (as early as c. 3700 BC), we see substantial evidence that selective breeding for more wool and thicker coats has begun to produce sheep as we know them. Domestication of course will have taken place quite a bit earlier (selective breeding is slow to produce such changes), perhaps around 10,000 BC in Mesopotamia, spreading to the Indus river valley by 7,000 BC and to southern France by 6,000 BC, while the replacement of many hair breeds of sheep with woolly sheep selectively bred for wool production in Northern Mesopotamia dates to the third century BC.1 That process of selective breeding has produced a wide variety of local breeds of sheep, which can vary based on the sort of wool they produce, but also fitness for local topography and conditions.

As we’ve already seen in our discussion on Steppe logistics, sheep are incredibly useful animals to raise as a herd of sheep can produce meat, milk, wool, hides and (in places where trees are scarce) dung for fuel. They also only require grass to survive and reproduce quickly; sheep gestate for just five months and then reach sexual maturity in just six months, allowing herds of sheep to reproduce to fill a pasture quickly, which is important especially if the intent is not merely to raise the sheep for wool but also for meat and hides. Since we’ve already been over the role that sheep fill in a nomadic, Eurasian context, I am instead going to focus on how sheep are raised in the agrarian context.

While it is possible to raise sheep via ranching (that is, by keeping them on a very large farm with enough pastureland to support them in that one expansive location) and indeed sheep are raised this way today (mostly in the Americas), this isn’t the dominant model for raising sheep in the pre-modern world or even in the modern world. Pre-modern societies generally operated under conditions where good farmland was scarce, so flat expanses of fertile land were likely to already be in use for traditional agriculture and thus unavailable for expansive ranching (though there does seem to be some exception to this in Britain in the late 1300s after the Black Death; the sudden increase in the cost of labor – due to so many of the laborers dying – seems to have incentivized turning farmland over to pasture since raising sheep was more labor efficient even if it was less land efficient and there was suddenly a shortage of labor and a surplus of land). Instead, for reasons we’ve already discussed, pastoralism tends to get pushed out of the best farmland and the areas nearest to towns by more intensive uses of the land like agriculture and horticulture, leaving most of the raising and herding of sheep to be done in the rougher more marginal lands, often in upland regions too rugged for farming but with enough grass to grow. The most common subsistence strategy for using this land is called transhumance.

Transhumant pastoralists are not “true” nomads; they maintain permanent dwellings. However, as the seasons change, the transhumant pastoralists will herd their flocks seasonally between different fixed pastures (typically a summer pasture and a winter pasture). Transhumance can be either vertical (going up or down hills or mountains) or horizontal (pastures at the same altitude are shifted between, to avoid exhausting the grass and sometimes to bring the herds closer to key markets at the appropriate time). In the settled, agrarian zone, vertical transhumance seems to be the most common by far, so that’s what we’re going to focus on, though much of what we’re going to talk about here is also applicable to systems of horizontal transhumance. This strategy could be practiced both over relatively short distances (often with relatively smaller flocks) and over large areas with significant transits (see the maps in this section; often very significant transits) between pastures; my impression is that the latter tends to also involve larger flocks and more workers in the operation. It generally seems to be the case that wool production tended towards the larger scale transhumance. The great advantage of this system is that it allows for disparate marginal (for agriculture) lands to be productively used to raise livestock.

This pattern of transhumant pastoralism has been dominant for a long time – long enough to leave permanent imprints on language. For instance, the Alps got that name from the Old High German alpa, alba meaning which indicated a mountain pasturage. And I should note that the success of this model of pastoralism is clearly conveyed by its durability; transhumant pastoralism is still practiced all over the world today, often in much the same way as it was centuries or millennia ago, with a dash of modern technology to make it a bit easier. That thought may seem strange to many Americans (for whom transhumance tends to seem very odd) but probably much less strange to readers almost anywhere else (including Europe) who may well have observed the continuing cycles of transhumant pastoralism (now often accomplished by moving the flocks by rail or truck rather than on the hoof) in their own countries.

For these pastoralists, home is a permanent dwelling, typically in a village in the valley or low-land area at the foot of the higher ground. That low-land will generally be where the winter pastures are. During the summer season, some of the shepherds – it does not generally require all of them as herds can be moved and watched with relatively few people – will drive the flocks of sheep up to the higher pastures, while the bulk of the population remains in the village below. This process of moving the sheep (or any livestock) over fairly long distances is called droving and such livestock is said to be moved “on the hoof” (assuming it isn’t, as in the modern world, transported by truck or rail). Sheep are fairly docile animals which herd together naturally and so a skilled drover can keep large flock of sheep together on their own, sometimes with the assistance of dogs bred and trained for the purpose, but just as frequently not. While cattle droving, especially in the United States, is often done from horseback, sheep and goats are generally moved with the drovers on foot.

Bret Devereaux, “Collections: Clothing, How Did They Make It? Part I: High Fiber”, A Collection of Unmitigated Pedantry, 2021-03-05.

1. On this, note E. Vila and D. Helmer, “The Expansion of Sheep Herding and the Development of Wool Production in the Ancient Near East” in Wool Economy in the Ancient Near East and the Aegean, eds. C. Breniquet and C. Michel (2014), which has the archaeozoological data).

August 9, 2024

Why Oil Paint Is So Expensive | So Expensive

Business Insider

Published Jul 13, 2019Oil paint is simple. At its most basic, it’s just a mixture of oil and pigment. But depending on the color and quality, a liter of this paint could cost you $285 to $1,100.

While the rise of oil paint is associated with the Renaissance, paintings using poppy-seed oil have been dated as far back as seventh-century Afghanistan. So what is it that makes this paint so special? And why is it so expensive?

(more…)

August 3, 2024

The Rise, Fall, And Revival Of Art Deco | A Style Is Born W/ @KazRowe

Wayfair

Published Jun 15, 2023Welcome to A Style is Born, hosted by YouTuber, cartoonist, and champion of under-represented history, Kaz Rowe!

Join us as we go down the rabbit hole and uncover the unique histories and origin stories behind your favorite design styles. In this first episode of Season 2, we delve into the history-rich Art Deco movement.

Chapters

Intro – 00:00

History – 00:45

Influences, Elements, & Materials – 04:58

1980s Art Deco Revival Via Memphis Group – 07:46

Conclusion – 09:13

(more…)

May 11, 2024

May 9, 2024

“The ability to believe entire gargling nonsense is strong in the [environmental] sector – as with this particular claim that we’re going to run out of rock”

Tim Worstall really, really enjoys kicking the stuffing out of strawman arguments, especially when they touch on something he’s very well informed about:

Some environmental claims are not just perfectly valid they’re essential for the continuation of life at any level above E. Coli. None of us would want the Thames to return to the state of 1950 when there was nothing living in it other than a collection of that E. Coli reflecting the interesting genetic and origin mix of the population of London. Sure, the arguments from Feargal and the like that a river running through 8 million people must be clean enough to swim in at all times is a bit extreme the other way around. One recent estimate has it that to perform that task for England would cost £260 billion — a few swimming baths sounds like a more sensible use of resources than getting all the rivers sparkling all the time.

Some are more arguable — violent and immediate climate change would be a bad idea, losing Lowestoft below the waves (possibly Dartford too) in 2500 AD might be something we can all live with. Arguable perhaps.

But some of these claims are wholly and entirely doolally. So much so that it’s difficult to imagine that grown adults take them seriously. But, sadly, they do and they do so on our money too.

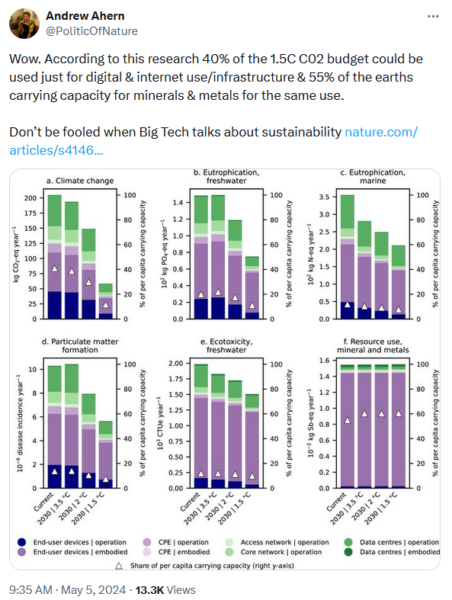

Wow. According to this research 40% of the 1.5C C02 budget could be used just for digital & internet use/infrastructure & 55% of the earths carrying capacity for minerals & metals for the same use.

The internet alone could use 55% of the Earth’s carrying capacity of metals and minerals? Well, to take that seriously is insane. That is not mere hyperbolic insult, that actually is insane. I write as someone who has written an entire book on this very subject (available here, for free, save your money to buy a subscription to this excellent Substack instead). There is no metal or mineral that we’re even going to run short of — in the technical, not economic, sense that is — for tens of millions of years yet. As the average lifetime of a species is perhaps 2 million years that should see us out.

So, clearly, they’re using some odd definition of how many minerals and metals we’ve got that we can use. I thought they’d do the usual Club of Rome thing (no, read the book to find out), confuse mineral reserves with what’s available and thus insist we all died last Tuesday afternoon. Rather to my surprise, no, they didn’t. They went further into raging lunacy.

It’s not wholly obvious as they don’t really quite announce their assumption, it’s necessary to track back a bit — and that’s a problem in itself. A top tip about scientific papers — if they say “As Bloggs said” then what that really means is that many people accept what Bloggs said as being true and also useful. You do not have to reprove Einstein every time you do physics, you can just say “As is known”. You’ve only got to reprove Al if that’s what you’re really trying to do.

Thus, if a definition is a referral back to something else, elsewhere, then you can be sure that the definition is a building block being used by others in their own papers. It’s a generalised insanity, not a specific one.

So, what is that limit?

Here we quantify the environmental impacts of digital content consumption encompassing all the necessary infrastructure linked to the consumption patterns of an average user. By applying the standardised life cycle assessment (LCA) methodology, we evaluate these impacts in relation to the per capita share of the Earth’s carrying capacity using 16 indicators related to climate change, nutrients flows, air pollution, toxicity, and resources use, for which explicit thresholds that should never be exceeded were defined

Now this is in Nature Communications. So it’s science. Even, it’s Science. It’s also lunatic. For, tracking back to try to find what those “resources use” are that will be 55% used up by the internet. It’s possible to think that maybe we’re going to use too much germanium in the glass in the fibreoptic cables say, or erbium in the repeaters, or … specific elements might be in short supply? As the book wot I wrote above points out, that’s nonsense. So, what is the claim?

Tracking back we get to this:

Resource use, mineral and metals MRD kg Sb eq Abiotic resource depletion (ADP ultimate reserves) 2.19E+08 3.18E-02 JRC calculation based on factor 2 concept Bringezu (2015); Buczko et al. (2016) Resource use

That’s from Table 3.

Which takes us one stage further back. This paper here is talking about Planetary Boundaries and as with the building block idea. PBs — I assume — make the assumption that Bringzeu, and Biczlo et al have given us a useful guide to what those PBs are. Which is why they just use their method, not invent a new one. But that, in turn, also means that other people working on PBs are likely to be using that same definition.

[…]

Note what they’re doing. Humans should not take out of that environment more than nature puts back into it each year. That’s some pretty dumb thinking there, as we don’t, when we use a metal or mineral — except in very rare circumstances — take it off planet. We move it around a bit, no more. But the claim really is that we should abstract, for use, no more than is naturally added back each year.

So, the correct limitation on our minerals use is how much magma volcanoes add each year.

No, really, humanity can use no more earth than gets thrown out of a volcano each year. That’s it. To use more would mean that we are depleting the stock and that’s not sustainable, see?

January 31, 2024

Don’t RUIN your workbench with 2x4s (use these tips instead)

Rex Krueger

Published 8 Nov 2023

(more…)

January 11, 2024

Art Deco Architecture

Prof. Lynne Porter

Published 22 Apr 2021Lecture for Fairfield University class called “What We Leave Behind: the History of Fashion & Decor”.