One of the most interesting things happening in the manufacturing world is the rise of a technology that may well make huge swathes of factories obsolete: practical 3D printing. What was originally just a neat way to develop small prototypes for mass production is quickly becoming a viable way to replace the entire mass production step. The technology is still limited to a small range of materials, but the price has been dropping steeply enough that small 3D printers are within the reach of hobbyists already.

The Economist points out that this will not be an unmixed blessing (as technological revolutions ever have been):

Others maintain that, by reducing the need for factory workers, 3D printing will undermine the advantage of low-cost, low-wage countries and thus repatriate manufacturing capacity to the rich world. It might; but Asian manufacturers are just as well placed as anyone else to adopt the technology. And even if 3D printing does bring manufacturing back to developed countries, it may not create many jobs, since it is less labour-intensive than standard manufacturing.

The technology will have implications not just for the distribution of capital and jobs, but also for intellectual-property (IP) rules. When objects can be described in a digital file, they become much easier to copy and distribute — and, of course, to pirate. Just ask the music industry. When the blueprints for a new toy, or a designer shoe, escape onto the internet, the chances that the owner of the IP will lose out are greater.

There are sure to be calls for restrictions on the use of 3D printers, and lawsuits about how existing IP laws should be applied. As with open-source software, new non-commercial models will emerge. It is unclear whether 3D printing requires existing rules to be tightened (which could hamper innovation) or loosened (which could encourage piracy). The lawyers are, no doubt, rubbing their hands.

Just as nobody could have predicted the impact of the steam engine in 1750 — or the printing press in 1450, or the transistor in 1950 — it is impossible to foresee the long-term impact of 3D printing. But the technology is coming, and it is likely to disrupt every field it touches. Companies, regulators and entrepreneurs should start thinking about it now. One thing, at least, seems clear: although 3D printing will create winners and losers in the short term, in the long run it will expand the realm of industry — and imagination.

So, even if you don’t have immediate plans to buy a 3D printer, you could do worse than to dust off your old drafting book and learn a bit of CAD. You may be using those skills sooner than you expect.

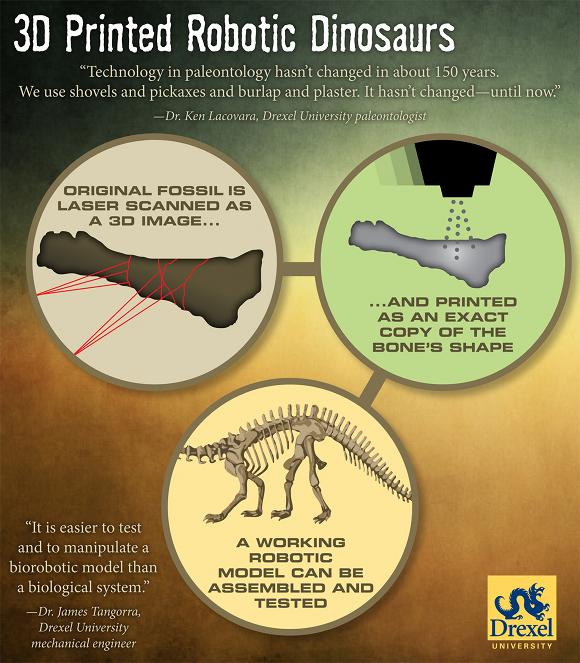

There’s more information (from 2009) on the 3D printing process here.