Christopher Schwarz

Published 8 Dec 2012Christopher Schwarz of Lost Art Press demonstrates the steps he takes to set up a new premium handplane.

November 18, 2019

Set Up a Handplane

October 16, 2019

Making a Scrub Plane – Convert your Stanley | Paul Sellers

Paul Sellers

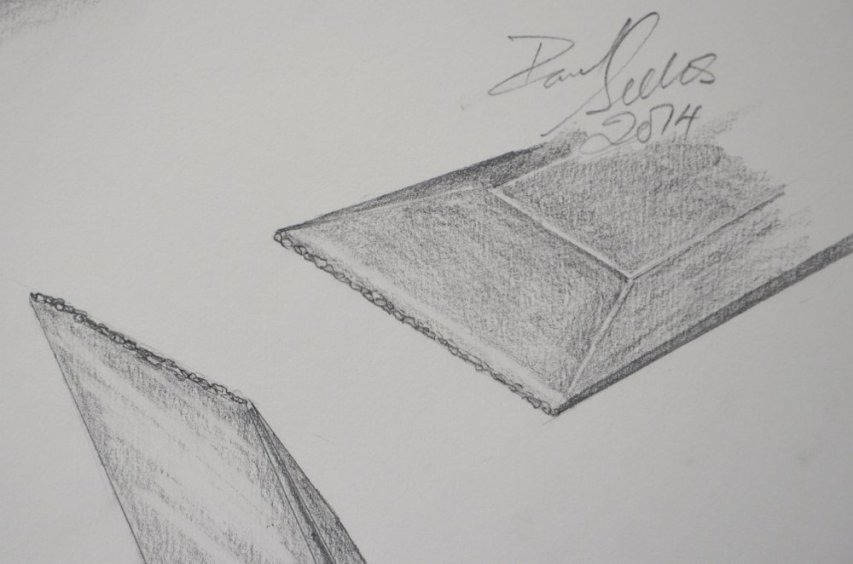

Published 25 Jul 2014Scrub planes are not exclusively used to mill wood to the required dimensions; they are also ideal for hogging off large amounts of wood in everyday woodworking situations.

In this video, Paul Sellers walks you through the steps to customise a basic No.4 Bailey pattern plane into a versatile and fully functional scrub plane, which will probably become one of your favourite plane additions. One great advantage about using a smoothing plane as a scrub plane is that it’s not irreversible; you can simply load it with a regular, un-fettled cutting iron again, and you can continue using the same plane as a smoothing plane.

To find out more about Paul Sellers and the projects he is involved with visit http://paulsellers.com

May 29, 2019

How to Sharpen a Router Plane | Paul Sellers

Paul Sellers

Published on 28 May 2019One of our most highly demanded videos is how to sharpen a router plane. Whether you have a new or second hand router plane, Paul Sellers’ sharpening method ensures you get the best performance from your router plane.

Want to learn more about woodworking? See https://woodworkingmasterclasses.com or https://commonwoodworking.com for step-by-step videos, guides and tutorials. You can also follow Paul’s latest ventures on his woodworking blog at https://paulsellers.com/

October 7, 2018

Paul Sellers | How to sharpen a handplane

Paul Sellers

Published on 7 Feb 2012Paul Sellers demonstrates how to sharpen a plane on diamond stones using a convex bevel method. To find out more about Paul Sellers or the projects he is involved with visit http://paulsellers.com.

September 27, 2018

How to Setup, Use and Sharpen a Plough Plane | Paul Sellers

Paul Sellers

Published on 7 Sep 2018Need to run some grooves and not sure where to start? Paul shows how to sharpen and prepare the plough plane for use, before showing the basics of how to cut a groove.

For more information on these topics, see https://paulsellers.com or https://woodworkingmasterclasses.com

August 11, 2018

Sharpening Stone Shelves | Paul Sellers

Paul Sellers

Published on 10 Aug 2018These shelves keep Paul’s sharpening stones close at hand for convenience and separate them from the rest of his tools as they can get dirty. Follow along to fit solid useful shelves at the end of your bench.

More info on the Workbench can be downloaded here:

https://paulsellers.com/paul-sellers-…There is more discussion on these videos on Woodworking Masterclasses. You can sign up (for free) here: https://woodworkingmasterclasses.com/…

Music credit:

Henry Horrell (https://soundcloud.com/henry-horrell)For more information on these topics, see https://paulsellers.com or https://woodworkingmasterclasses.com

June 12, 2018

How to Make a Strop | Paul Sellers

Paul Sellers

Published on 22 May 2018A strop enables you to sharpen your bladed tools to another level. Made from a simple block of ply, this quick and easy tutorial shows you how to make your own with minimal materials.

For more information on these topics, see https://paulsellers.com or https://woodworkingmasterclasses.com

May 5, 2018

Cabinet Scraper Honing Guide | Paul Sellers

Paul Sellers

Published on 13 Apr 2018Getting a crisp 45° bevel on your cabinet scraper can be tricky. Paul shows how to make and use a honing guide that gives you a guaranteed angle every time.

For more information on these topics, see https://paulsellers.com or https://woodworkingmasterclasses.com

February 17, 2018

How to Correct New Saws | Paul Sellers

Paul Sellers

Published on 16 Feb 2018What do you have to do to a saw you’ve just bought to get it ready for work? Paul takes a few minutes to show what it takes to get as saw cutting beautifully.

For more information on these topics, see https://paulsellers.com or https://woodworkingmasterclasses.com

September 29, 2017

How to Make a Sharpening Plate Holder | Paul Sellers

Paul Sellers

Published on 18 Sep 2017The sharpening plate holder is used daily and is a vital part of Paul’s sharpening system. Paul shows how to make your own using just a few hand tools. It holds the stones securely, keeping them in order from coarse to fine, which means you can easily pull it out and be ready for a quick sharpen.

For more information on these topics, see https://paulsellers.com or https://woodworkingmasterclasses.com

March 3, 2017

Sharpening a Chisel with Paul Sellers

Published on 27 Feb 2017

Chisels come from the manufacturer needing preparing or initialising as well sharpening. How do you check they are flat and get them sharp? Paul shows you the process he follows. This gets them to the level we need for crisp and accurate work.

For more information on these topics, see https://paulsellers.com or https://woodworkingmasterclasses.com

December 13, 2015

How to Sharpen a Knife with Paul Sellers

Published on 11 Dec 2015

Paul shows his very simple method of how to get a razor sharp edge on your kitchen, carving, pocket or any form of knife using just a few pieces of sandpaper or some diamond paddles.

July 27, 2015

Sharpening and Setting the Bench Plane with Paul Sellers

Published on 23 Jul 2015

Paul Sellers shows how he sharpens and sets a bench plane in his every day of work. A quick and easy guide to get your plane working.

October 25, 2014

Sharpening woodworking tools

Paul Sellers talks about the practical limits to sharpening woodworking tools like planes and chisels:

As I have said, we have become something of an obsessive bunch when it comes to the different elements of working wood; sharpness has become more and more obsessive. Now we are not talking about the violin maker seeking sharp levels for clear tone from the wood and who uses wood so soft, unsharp gouges and planes would bruise rather than cut the fine surfaces he strives to achieve. His standards parallel the levels needed for severing tissue by the surgeon’s hand, not the bench joiner chopping mortises and cutting a few dovetails.

It’s unfortunate that since the demise of ordinary craftsmanship we now turn to guru wood writers and not wood-wrights. Woodwrights are no longer there to give us our information of course. It’s true too that the sources of information become more and more questionable. Three recent sources of information teaching on sharpening techniques I tracked back to tool catalog and online sales people selling products for sharpening. Most of the information they have is not new but regurgitated. Each phase of sharpening change marks another saleable product and so we see Japanese water stones added to carborundum stones, Arkansas stones and Washita stones and then came diamonds and abrasive films, diamond paste and flattening stones. The list goes on.

We have survived the different gospels of scary sharp and micro-bevel methodology and are emerging to this very simple reality. As long as you start the cutting edge somewhere around 30-degrees and polish it out it will cut well. If you you sharpen to around 1200-grit it will cut most anything you need in woodworking. If you sharpen to a polished edge of around 15,000-grit you can slice the most delicate of materials effortlessly, but 98% of the time that’s far from necessary. What am I saying? I’m saying that we generally sharpen to task but often sharpen to a higher level because it’s not much extra effort. We all know after a few efforts at sharpening that the greatest effort comes at the start of the process when we have to regain ground to get through a fractured and dulled edge and back to a productive cutting edge. That said, it’s not a big deal, just a few extra strokes on the coarse diamonds gets you there. So, if that is the case, why do we sharpen to higher levels than are usually needed. Well, it is a fact that the more polished the two plains forming the arête for a cutting edge are, the sharper the edge is but the stronger the edge is too. As I said, the extra effort is worth the work because it’s so quick and effective. It’s not so much what we do to the edge to establish it but what we do to the edge after we have prepared it for work. Taking the chisel to the surface of the wood to work the wood begins an immediate process of edge reduction we now know is edge fracture but was once called wear. No matter the steel, edge fracture occurs at some level but some steels fracture more readily than others. What we often do not realise is that it is impossible to find a steel that both takes and retains an edge and at the same time has a level of durability we can rely on forever. All edges wear away by fracture and constantly need restoring.

September 2, 2014

Sharpening woodworking tools

I’m an occasional woodworker, but I’m always aware I don’t sharpen my tools as often as I should. One of the reasons I don’t is that it’s such a hassle to sharpen them properly: it’s not as simple as sharpening a kitchen knife, and you need to spend time to work through from a coarse grit (250 or so), through medium grit (1000) and into fine (4000) or even superfine (15000 and higher). This video by Paul Sellers has persuaded me that it doesn’t have to be that way for most of the woodworking hand tools I’m likely to use:

Published on 8 Nov 2013

In this video Paul Sellers shows that you don’t need to sharpen to 15,000+ grit on you planes, chisels and other woodworking tools. 250-grit works just fine for most of our woodwork. Paul addresses the myths and misinformation put forward, and challenges what we think about sharpening.

To find out more about Paul Sellers and the work he is involved with visit http://paulsellers.com