Matt Estlea

Published on 21 May 2019In this video, I have a go at making a hexagonal bowl and inadvertently end up making a lethal weapon.

________________________________________________________________Support what I do by becoming a Patron! This will help fund new tools, equipment and cover my overheads. Meaning I can continue to bring you regular, high quality, free content. Thank you so much for your support! https://www.patreon.com/mattestlea

________________________________________________________________See what tools I use here: https://kit.com/MattEstlea

My Website: http://www.mattestlea.com

________________________________________________________________My name is Matt Estlea, I’m a 23 year old Woodworker from Basingstoke in England and my aim is to make your woodworking less s***.

I come from 5 years tuition at Rycotewood Furniture Centre with a further 1 year working as an Artist in Residence at the Sylva Foundation. I now teach City and Guilds Furniture Making at Rycotewood as of September 2018.

I also had 5 years of experience working at Axminster Tools and Machinery where I helped customers with purchasing tools, demonstrated in stores and events, and gained extensive knowledge about a variety of tools and brands.

During the week, I film woodworking projects, tutorials, reviews and a viewer favourite ‘Tool Duel’ where I compare two competitive manufacturers tools against one another to find out which is best.

I like to have a laugh and my videos are quite fast paced BUT you will learn a lot, I assure you.

Lets go make a mess.

May 22, 2019

Making a Hexagonal Bowl | Turning Tuesday

May 21, 2019

Tips for Cleaner Miter Saw Cuts

WoodworkersJournal

Published on 8 Oct 2015Eliminate tearout and take your saw’s cutting performance to the next level quickly and easily.

Visit our website for the best woodworking projects and lessons:

http://www.woodworkersjournal.com/

May 19, 2019

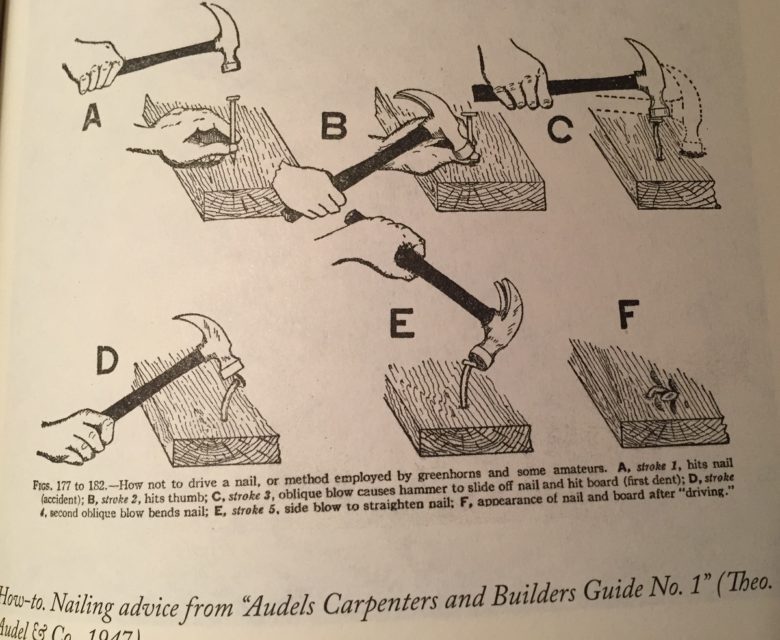

How not to drive a nail

In Christopher Schwarz’s recent The Anarchist’s Design Book, he includes a set of illustrations from a 1947 publication, which appear to still be 100% accurate:

May 18, 2019

The Paul Sellers Plywood Workbench | Episode 7

Paul Sellers

Published on 17 May 2019The completion of any project should always be exciting but when it’s your workbench there is something really special and unique about it. In this episode Paul uses methods for installing and fitting the bench vise which he has developed to guarantee a rock solid fit. The vise is, of course, your third hand. You do not want one ounce of movement in it. The jaw liners too must match the vise and the workbench for solidity. It’s all lifetime stuff for living woodworkers with style.

Want to learn more about woodworking? See https://woodworkingmasterclasses.com or https://commonwoodworking.com for step-by-step videos, guides and tutorials. You can also follow Paul’s latest ventures on his woodworking blog at https://paulsellers.com/

May 13, 2019

Clamp Retrofit | Paul Sellers

Paul Sellers

Published on 15 Jul 2016Clamps are an essential piece of equipment around the workshop. Paul shows how he retrofits a standard aluminium sash clamp to be much more effective.

For more information on these topics, see https://paulsellers.com or https://woodworkingmasterclasses.com

May 12, 2019

CRAZY easy way to straighten a rough board or cut a taper

Stumpy Nubs

Published on 9 Apr 2019When you use this link to visit our sponsor, you support us►

SaburrTooth Carving Tools: http://www.saburrtooth.com/

Subscribe (free) to Stumpy Nubs Woodworking Journal e-Magazine► http://www.stumpynubs.com/subscribe.html

May 9, 2019

Spokeshave Q&A | Paul Sellers

Paul Sellers

Published on 8 May 2019The spokeshave is a far more important tool than we might understand so we’d like to make it more understandable for you. Paul considers the spokeshave to be one of the most undervalued and underestimated tools and one he cannot imagine his own woodworking life without. We’ve had many questions over the years about spokeshaves and thought it would be a good idea to follow on from the coping saw Q&A with a whole Q&A dedicated to this amazingly versatile hand tool.

Questions:

0:37 Which is the most versatile spokeshave? Which one will accomplish more tasks than the others, and which ones are your favourites?

1:36 When would I use a curved bottom spokeshave as opposed to a flat bottom?

5:13 What would be a good beginners spokeshave?

6:15 If you were going to own two spokeshaves, what would they be?

7:14 I have a Millers Falls No. 1 cigar spokeshave and find it almost impossible to get a shaving from. Do you have input on adjusting and also sharpening the blade?

7:44 Is your blade sharpened straight across, or does it have a slight crown side to side, like some smoothing planes?

8:33 I have my spokeshave bevels at 30 degrees, would 25 degrees be better?

10:10 [How do you] sharpen wooden spokeshaves? The blades seem so different from the cast handle spokeshaves which have blades like small planes.

11:42 When do you push vs. pull the tool?

13:20 How do you prevent chatter that is a result of the small surface area on the base of the spokeshave?

15:22 Are there any issues with having the spokeshave set for a lighter shave on end and a heavier shave on the other end?

16:36 How do I get an extremely fine cut when shaping curves

17:46 Is there a modification or adjustment to keep chips getting jammed under the blade.

20:11 How do I keep the spokeshave sole parallel to the flat surface or at the correct angle to the curved surface to get consistent shavings? It looks like I have to apply some force to tilt it a bit forward but my hands don’t feel when it is in the correct position.

22:11 I noticed you perform straight planing with the spokeshave over wood wider than the blade itself, and get super thin shavings. Can you explain how you set the spokeshave for this?

23:56 I recently bought a wooden spokeshave and often find the blade works itself loose after a few passes, i close the mouth of the plane as much as possible but still find after a few passes it opens up and needs adjusting again.

25:40 Why are there two blade adjustment screws?

26:24 Are new cheap generic spokeshaves restorable? If not, what makes them unusable? I regret getting one of these, but it was also crazy cheap, so this information would help me understand what to look for in good ones.

27:35 I have a couple of wooden spokeshaves that I have trouble getting to work. The soles of these spokeshaves are quite worn out, so the mouth is very wide. I can’t seem to get thin shavings. I haven’t found any that don’t have this so can’t figure out if this is down to my technique or the tool. My question is: how can you tell when the sole of a wooden spokeshave needs fixing and how do you set the blade properly to get thin shavings?

30:31 Is the blade inserted bevel up or down?

32:03 The Stanley spokeshave I purchased online is a bit “rough” to say the least. Does one need to “prepare” it like with a handplane (flattening the sole and such)?Click the link below to read more about the uses of spokeshaves: https://paulsellers.com/2019/03/a-spo…

For exercises that will work on your control of the flat-bottomed spokeshave and establish good patterns for continuously reading the grain visit: https://commonwoodworking.com/spokesh…

Want to make your very own wooden spokeshave? See: https://woodworkingmasterclasses.com/…

Equipment Review: The Best Heavy Duty Cutting Boards

America’s Test Kitchen

Published on 5 Apr 2019Each cutting board model had its fans. But a few factors made certain boards more durable, more pleasant to cut on, and more foolproof to maintain.

Buy our winning heavy-duty cutting board: https://cooks.io/2HZ4oOc

Behind the testing: https://cooks.io/2Ie5yF0

Full testing details and ranking chart: https://cooks.io/2CSPWTBWatch more equipment reviews: https://www.youtube.com/watch?v=KDfNw…

ABOUT US: Located in Boston’s Seaport District in the historic Innovation and Design Building, America’s Test Kitchen features 15,000 square feet of kitchen space including multiple photography and video studios. It is the home of Cook’s Illustrated magazine and Cook’s Country magazine and is the workday destination for more than 60 test cooks, editors, and cookware specialists. Our mission is to test recipes over and over again until we understand how and why they work and until we arrive at the best version.

May 8, 2019

Making Door Pulls | Turning Tuesday #15

Matt Estlea

Published on 7 May 2019In this video, I make some door pulls for the Router Bit Cabinet I am currently making. If you’re interested in watching this series, you can do so here:

https://www.youtube.com/watch?v=Cgxp9…

_________________________________________________________________Support what I do by becoming a Patron! This will help fund new tools, equipment and cover my overheads. Meaning I can continue to bring you regular, high quality, free content. Thank you so much for your support! https://www.patreon.com/mattestlea

_________________________________________________________________See what tools I use here: https://kit.com/MattEstlea

My Website: http://www.mattestlea.com

_________________________________________________________________My name is Matt Estlea, I’m a 23 year old Woodworker from Basingstoke in England and my aim is to make your woodworking less s***.

I come from 5 years tuition at Rycotewood Furniture Centre with a further 1 year working as an Artist in Residence at the Sylva Foundation. I now teach City and Guilds Furniture Making at Rycotewood as of September 2018.

I also had 5 years of experience working at Axminster Tools and Machinery where I helped customers with purchasing tools, demonstrated in stores and events, and gained extensive knowledge about a variety of tools and brands.

During the week, I film woodworking projects, tutorials, reviews and a viewer favourite ‘Tool Duel’ where I compare two competitive manufacturers tools against one another to find out which is best.

I like to have a laugh and my videos are quite fast paced BUT you will learn a lot, I assure you.

Lets go make a mess.

May 4, 2019

The Paul Sellers Plywood Workbench | Episode 6

Paul Sellers

Published on 3 May 2019Paul is now on the last few steps of completing the construction of the bench itself. He starts this episode by cutting and fitting the wellboard. Paul continues to cut two pieces of wood on the bandsaw, which are then glued in place on top of the wellboard. Once this is all finished, Paul moves on to retracting the screws from both apron pieces and replacing them with bolts. He then moves on to the finishing stages of planning the benchtop and making all things smooth. Paul then ends this episode by applying two coats of water-based finish.

Episode 7 will be released on YouTube on the 17th of May but you can watch it right now at https://woodworkingmasterclasses.com/…

Want to learn more about woodworking? See https://woodworkingmasterclasses.com or https://commonwoodworking.com for step-by-step videos, guides and tutorials. You can also follow Paul’s latest ventures on his woodworking blog at https://paulsellers.com/

May 3, 2019

Making a Router Bit Cabinet – Part 4

Matt Estlea

Published on 2 May 2019In this video I create the router bit holders and get the doors attached!

_Support what I do by becoming a Patron! This will help fund new tools, equipment and cover my overheads. Meaning I can continue to bring you regular, high quality, free content. Thank you so much for your support! https://www.patreon.com/mattestlea

_See what tools I use here: https://kit.com/MattEstlea

My Website: http://www.mattestlea.com

_My name is Matt Estlea, I’m a 23 year old Woodworker from Basingstoke in England and my aim is to make your woodworking less s***.

I come from 5 years tuition at Rycotewood Furniture Centre with a further 1 year working as an Artist in Residence at the Sylva Foundation. I now teach City and Guilds Furniture Making at Rycotewood as of September 2018.

I also had 5 years of experience working at Axminster Tools and Machinery where I helped customers with purchasing tools, demonstrated in stores and events, and gained extensive knowledge about a variety of tools and brands.

During the week, I film woodworking projects, tutorials, reviews and a viewer favourite ‘Tool Duel’ where I compare two competitive manufacturers tools against one another to find out which is best.

I like to have a laugh and my videos are quite fast paced BUT you will learn a lot, I assure you.

Lets go make a mess.

May 2, 2019

Natural Edged Bowl with Bronze Powder | Turning Tuesday #14

Matt Estlea

Published on 30 Apr 2019In this video, I begin by making a natural edged bowl but then kind of lose my mind and start adding metal, and fire, and more metal….. and more fire.

_________________________________________________________________Support what I do by becoming a Patron! This will help fund new tools, equipment and cover my overheads. Meaning I can continue to bring you regular, high quality, free content. Thank you so much for your support! https://www.patreon.com/mattestlea

_________________________________________________________________See what tools I use here: https://kit.com/MattEstlea

My Website: http://www.mattestlea.com

_________________________________________________________________My name is Matt Estlea, I’m a 23 year old Woodworker from Basingstoke in England and my aim is to make your woodworking less s***.

I come from 5 years tuition at Rycotewood Furniture Centre with a further 1 year working as an Artist in Residence at the Sylva Foundation. I now teach City and Guilds Furniture Making at Rycotewood as of September 2018.

I also had 5 years of experience working at Axminster Tools and Machinery where I helped customers with purchasing tools, demonstrated in stores and events, and gained extensive knowledge about a variety of tools and brands.

During the week, I film woodworking projects, tutorials, reviews and a viewer favourite ‘Tool Duel’ where I compare two competitive manufacturers tools against one another to find out which is best.

I like to have a laugh and my videos are quite fast paced BUT you will learn a lot, I assure you.

Lets go make a mess.

April 27, 2019

Making a Router Bit Cabinet – Part 3

Matt Estlea

Published on 25 Apr 2019In this video, I cut out the perspex for the top of the panelled doors, shaped the mystery material for the bottom panels and then stuck it all together! Oh, and Rob bullies me some more.

_________________________________________________________________________________________________

Support what I do by becoming a Patron! This will help fund new tools, equipment and cover my overheads. Meaning I can continue to bring you regular, high quality, free content. Thank you so much for your support! https://www.patreon.com/mattestlea

_________________________________________________________________________________________________

See what tools I use here: https://kit.com/MattEstlea

My Website: http://www.mattestlea.com

_________________________________________________________________________________________________

My name is Matt Estlea, I’m a 23 year old Woodworker from Basingstoke in England and my aim is to make your woodworking less s***.I come from 5 years tuition at Rycotewood Furniture Centre with a further 1 year working as an Artist in Residence at the Sylva Foundation. I now teach City and Guilds Furniture Making at Rycotewood as of September 2018.

I also had 5 years of experience working at Axminster Tools and Machinery where I helped customers with purchasing tools, demonstrated in stores and events, and gained extensive knowledge about a variety of tools and brands.

During the week, I film woodworking projects, tutorials, reviews and a viewer favourite ‘Tool Duel’ where I compare two competitive manufacturers tools against one another to find out which is best.

I like to have a laugh and my videos are quite fast paced BUT you will learn a lot, I assure you.

Lets go make a mess.

April 26, 2019

Tips on Accurate Sawing

RobCosman.com

Published on 22 Mar 2019I was teaching a dovetail workshop recently and while watching a student struggle to get the saw started I noticed the angle he was approaching the board. I realized I have never addressed this problem so here it is along with the simple solution. Result should be more accurate dovetails from the saw!

April 20, 2019

Making a Router Bit Cabinet – Part 2

Matt Estlea

Published on 18 Apr 2019In this video, I get cutting the grooves for the back panel, the shelf, and refine the mitred dovetails and then get the cabinet glued together!

_________________________________________________________________________________________________

Support what I do by becoming a Patron! This will help fund new tools, equipment and cover my overheads. Meaning I can continue to bring you regular, high quality, free content. Thank you so much for your support! https://www.patreon.com/mattestlea

_________________________________________________________________________________________________

See what tools I use here: https://kit.com/MattEstlea

My Website: http://www.mattestlea.com

_________________________________________________________________________________________________

My name is Matt Estlea, I’m a 23 year old Woodworker from Basingstoke in England and my aim is to make your woodworking less s***.I come from 5 years tuition at Rycotewood Furniture Centre with a further 1 year working as an Artist in Residence at the Sylva Foundation. I now teach City and Guilds Furniture Making at Rycotewood as of September 2018.

I also had 5 years of experience working at Axminster Tools and Machinery where I helped customers with purchasing tools, demonstrated in stores and events, and gained extensive knowledge about a variety of tools and brands.

During the week, I film woodworking projects, tutorials, reviews and a viewer favourite “Tool Duel” where I compare two competitive manufacturers’ tools against one another to find out which is best.

I like to have a laugh and my videos are quite fast paced BUT you will learn a lot, I assure you.

Lets go make a mess.