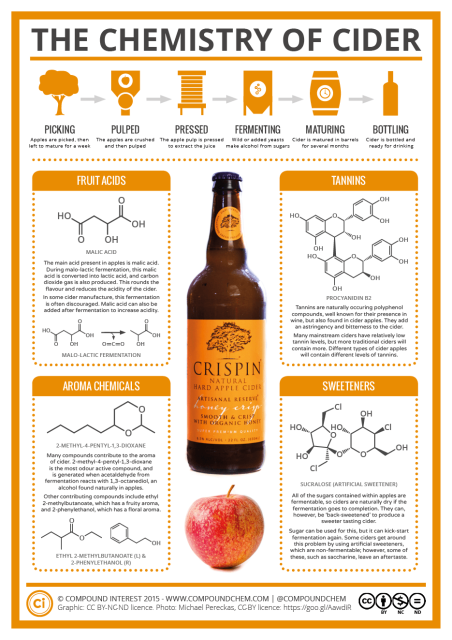

At Compound Interest, a look at the making of cider:

On a hot summer’s day, the cool, refreshing taste of cider is hard to beat. But what are the chemicals behind this flavour?

Before we look at the chemistry, let’s briefly discuss how cider is made. Obviously, it starts with the apples being picked from the tree. The type of apples is, of course, a major factor in the taste of the finished cider. Bittersweet cider apples are low on acidity, but high on tannins, whilst sharp apples are the opposite. Sweet apples, meanwhile, are low in both departments, whilst bittersharp apples are high in both.

Once the apples have been picked, they’re left to mature for a time before then being scratted, or ground down, into a pulp. The pulp produced by this process is known as pomace. This pomace is then pressed to squeeze out all of the juice, which is collected into either vats or casks. At this point, it is then slowly fermented, and yeasts convert the natural sugars in the apples into alcohol. These yeasts can be the natural yeasts present in the apples, or yeasts that are added specifically for fermentation.

After fermentation is complete, the cider will often be left to mature for several months. At this point, extra sugar is sometimes added to the cider to allow fermentation to continue, and produce a small amount of carbon dioxide to carbonate the cider. However, commercially carbonation is often primarily accomplished via direct injection of carbon dioxide. In the manufacture of some ciders, they may be blended with other, older ciders, to ensure consistency of taste or to alter the flavour.