At TechHive, Kevin Lee reports on a different kind of 3D printing effort:

I sat on a 3D-printed bench.

“Durability” and “strength” are about the last words I would ever associate with 3D printing. But I’m not talking about the small, plastic trinkets you would print out with your MakerBot. This is Emerging Objects, a small fabrication studio in Oakland, CA that’s researching how to 3D-print using materials like wood, ceramic, newspaper, concrete, and salt.

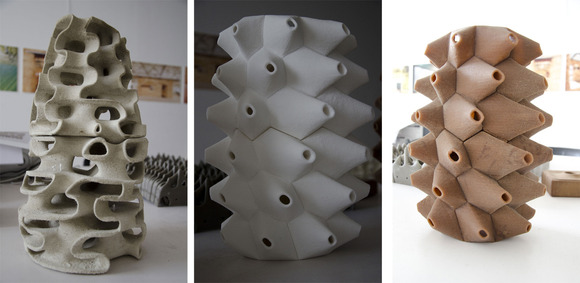

Some 3D-printed art pieces made from newspaper, salt, and maple wood.

“Everyone is focusing on machines, and we’re interested in what machines can make,” Emerging Objects co-founder Ronald Rael explained to TechHive. “We saw a limitation in what a machine can make because of the medium, and so we wondered if we could reformulate that media to suit our own architectural agendas to print big.”

As with the report last week about the chap 3D-printing his own Aston Martin replica, the small size of the individual printed units is a bottleneck for producing larger objects. Using a 3D printer to produce key components while using ordinary production methods for larger pieces is the economical way to work right now. That is bound to change as the technology improves, but practical limits on size and cost will continue at the “consumer” end of the 3D printer market.

According to Rael, powder-based 3D printing was one of the very first 3D printing technologies to come into being. It hasn’t really caught on, however, because the machines are so much more expensive than other types of 3D printers. On the other hand, the fused deposition modeling (FDM) method, which lays down thin layers of hot extruded plastic to create objects, has become popular among makers thanks to its accessibility and relative affordability.

All that said, Rael still sees a promising future for powder-based 3D printing.

“We have a [powder] printing technology that I think is very open-ended in terms of the kind of materials that can be in it. Then we have [a FDM] one that’s very closed and that’s the much more popular version,” he explained. “While I like those kinds of printers, […] I think the big future is in store for powder printing.”